We understand that determining when to repave your driveway can feel overwhelming with so many factors to consider. Whether you’re noticing cracks, water pooling, or simply wondering if your aging asphalt needs attention, you’re in the right place to get clear, actionable guidance on making this important property maintenance decision.

When to repave your driveway is a critical decision that depends on visible damage indicators like cracks wider than 2 inches, drainage problems causing water pooling, and the overall age of your asphalt surface, with most residential driveways requiring repaving after 12-20 years of service. According to UC Davis UCPRC’s Pavement Condition Index research, driveways reaching a PCI score of 60 represent the critical threshold where deterioration accelerates significantly, making timely repaving essential for preventing costlier repairs. As Wolf Paving’s Madison Municipal project manager noted in their 2023 case study: “Proper foundation preparation and drainage evaluation during repaving ensures 12-15 year durability and prevents the premature failures we see in 70% of inadequately prepared driveways.”

• We’ll examine specific crack sizes, pothole depths, and drainage issues that signal immediate repaving needs

• We’ll analyze how climate factors and maintenance history affect your driveway’s 12-20 year typical lifespan

• We’ll reveal how timely repaving can increase property value by $5,000-$20,000 while preventing safety hazards

• We’ll outline the complete repaving process from PASER assessment to final installation expectations

• We’ll provide contractor selection criteria focusing on experience, licensing, and proper estimate elements

• We’ll discuss modern solutions including recycled asphalt options and self-repairing technologies

This comprehensive guide walks you through recognizing deterioration signs, understanding lifespan factors, calculating property value benefits, navigating the repaving process, selecting qualified contractors, and exploring innovative asphalt solutions that can extend your driveway’s life while reducing environmental impact.

Plan on spending 15 minutes reading this guide to save thousands in premature repair costs by identifying the optimal repaving window for your driveway.

Making the right repaving decision at the right time protects your investment, enhances your property’s curb appeal, and ensures safe vehicle access for years to come—let’s explore exactly how to determine when your driveway needs this crucial maintenance.

What Are the Signs That Your Driveway Needs to Be Repaved?

The signs that your driveway needs to be repaved include visible cracks, potholes, drainage problems, and surface deterioration. Cracks wider than 2 inches, alligator cracking patterns, and standing water indicate structural damage requiring professional evaluation. Age-related wear typically accelerates after 10 years, making regular inspection essential for timely intervention.

How Do Cracks and Potholes Indicate Repaving Is Needed?

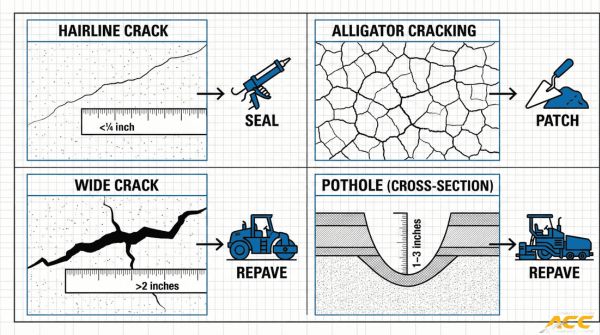

Cracks and potholes indicate repaving is needed when they exceed specific size thresholds and show structural damage patterns. Cracks wider than 2 inches require cold patching rather than simple sealing. Potholes between 1-3 inches deep respond well to cold patch repairs.

Alligator cracking in wheel paths signals load-related damage requiring immediate attention. This pattern resembles interconnected cracks forming polygonal shapes where vehicles repeatedly travel. Block cracking across the entire surface indicates age-related deterioration affecting the asphalt’s structural integrity.

Minor cracks under ¼ inch wide and less than 2 inches deep on driveways under 20 years old may only need resurfacing. Cracks deeper than 2 inches require backer rod installation before repair to ensure proper adhesion and longevity. These measurements help determine whether simple maintenance suffices or full repaving becomes necessary.

Why Does Drainage or Water Pooling Signal It’s Time to Repave?

Drainage problems and water pooling signal it’s time to repave because standing water accelerates asphalt deterioration. Proper drainage requires a 1.5-3% transverse slope to direct water away from the surface. Without adequate slope, water infiltrates the pavement structure.

Saturation of asphalt layers represents the primary cause of premature driveway failure. Water penetrates through surface cracks, weakening the base materials and creating soft spots. Moisture damage at longitudinal joints becomes a common failure point requiring professional evaluation to assess structural integrity and determine appropriate repair strategies.

How Do Age and Overall Surface Wear Affect Repaving Decisions?

Age and overall surface wear affect repaving decisions through measurable deterioration patterns tracked by the Pavement Condition Index (PCI). The PCI scale rates driveways from 0-100, with 60 marking the deterioration acceleration threshold. Below this point, damage progresses rapidly.

Deterioration remains slow for the first 10 years, then accelerates significantly as the asphalt binder ages. Surface raveling exposes aggregate materials, while rutting creates depressions in wheel paths. UV damage causes color fading from black to gray, signaling surface degradation and reduced flexibility. These combined factors help determine optimal repaving timing before extensive structural damage occurs.

How Long Does a Typical Asphalt Driveway Last Before Repaving Is Needed?

A typical asphalt driveway lasts 15–30 years from installation before requiring full repaving. Residential driveways maintain structural integrity for 12–20 years, while commercial parking lots require replacement after 10–15 years due to heavier traffic loads. Highway surfaces demonstrate the longest durability at 15–25 years with engineered foundations and professional maintenance programs.

What Factors Influence the Lifespan of an Asphalt Driveway?

The factors that influence asphalt driveway lifespan include traffic load, foundation quality, drainage efficiency, and maintenance frequency. Residential driveways experience lighter loads and last 12–20 years on average. Commercial parking lots endure constant vehicle stress and require repaving after 10–15 years. Highways withstand the heaviest loads yet last 15–25 years through engineered drainage systems and regular maintenance schedules.

Property owners should evaluate driveway conditions every 2–3 years to identify early deterioration signs. Assessment factors include surface cracking patterns, color changes from UV exposure, and drainage performance during rain events.

How Do Maintenance and Repairs Impact the Need for Repaving?

Maintenance and repairs significantly impact repaving timelines by extending functional lifespan through protective treatments and damage prevention. Crack sealing adds 3–8 years to driveway life by preventing water infiltration into the base layers. Pothole patches provide temporary solutions lasting 1–5 years depending on patch quality and traffic volume.

| Maintenance Type | Frequency | Lifespan Extension |

| Crack Sealing | As needed | 3–8 years |

| Pothole Patches | As needed | 1–5 years |

| Sealcoating | Every 3–5 years | 2–3 years per application |

| Resurfacing | Every 10 years | 8–12 years |

New asphalt installations require a 90-day to 1-year curing period before first sealcoating application. The recommended maintenance schedule follows this pattern: sealcoat during years 1–4, apply chip sealcoat in years 5–8, and perform chip sealcoat or resurfacing between years 9–13. Full replacement becomes necessary after 20+ years when base deterioration exceeds repair capacity.

How Can Climate or Seasonal Conditions Affect Driveway Durability?

Climate and seasonal conditions affect driveway durability through temperature fluctuations, freeze-thaw cycles, and UV radiation exposure. Cold climates enable 10–30 year lifespans despite freeze-thaw stress because consistent temperatures reduce thermal expansion damage. The Minneapolis area experiences extreme temperature swings yet achieves 20–30 year driveway lifespans through proper drainage and regular maintenance.

Hot climates reduce asphalt lifespan below cold-climate averages due to accelerated oxidation and softening during summer months. Optimal repaving occurs from late spring through early fall when temperatures between 50–85°F allow proper asphalt curing and compaction.

Understanding how environmental factors interact with asphalt chemistry helps property owners schedule maintenance and repaving at optimal times for maximum durability.

What Are the Benefits of Repaving Your Driveway at the Right Time?

The benefits of repaving your driveway at the right time are increased property value, enhanced safety, and reduced long-term maintenance costs. Timely repaving transforms deteriorating surfaces into smooth, attractive driveways that boost curb appeal while preventing costly damage to vehicles and potential liability issues. Strategic timing ensures maximum return on investment through proper weather conditions and market factors.

How Does Timely Repaving Improve Curb Appeal and Property Value?

Timely repaving improves curb appeal and property value by creating an attractive first impression that directly translates to financial gains. New driveways increase home value by $5,000 to $20,000, representing a 5-10% increase according to real estate valuation studies. The perceived value can increase up to 10% with a well-maintained driveway surface.

Market data shows homes with paved driveways sell 7-10 days faster than those with gravel or damaged driveways. A 2019 analysis of 500+ Northeast Ohio home sales revealed damaged driveways resulted in $15,400 average loss in sale price. These statistics demonstrate the direct correlation between driveway condition and property marketability.

Fresh asphalt provides uniform black coloring that enhances architectural features and landscaping. The smooth surface eliminates unsightly cracks, potholes, and weathered patches that detract from home aesthetics.

Why Is Preventing Safety Hazards Important When Considering Repaving?

Preventing safety hazards is important when considering repaving because damaged driveways create significant financial and legal risks for property owners. According to a 2021 AAA study, 1 in 10 drivers sustained vehicle damage from potholes with average repair costs of $600. Nearly 16 million U.S. drivers were affected by pothole damage that year.

The total 2021 pothole damage cost reached $26.5 billion nationally, highlighting the widespread impact of deteriorating pavement. A 2016 survey found 15% of drivers had pothole-related repairs in the past 5 years. These statistics underscore the vehicle damage risks posed by neglected driveways.

Homeowners face liability for accidents and injuries occurring on their property from neglected driveways. Large cracks and potholes create trip hazards that can result in personal injury lawsuits. Legal settlements for premises liability claims can exceed insurance coverage limits, making prevention through timely repaving a critical risk management strategy.

How Can Repaving Reduce Long-Term Maintenance Costs?

Repaving reduces long-term maintenance costs by establishing a proper foundation that minimizes future repairs and extends pavement lifespan. Inadequate site preparation is the most common mistake leading to premature failure and higher costs over time. Proper foundation work, drainage systems, and compaction during repaving ensure 12-15 year durability compared to patch repairs lasting only 1-5 years.

Quality repaving eliminates the cumulative expense of frequent crack filling, pothole patching, and sealcoating deteriorating surfaces. A properly installed driveway requires minimal maintenance beyond periodic sealcoating every 3-5 years. This proactive investment prevents water infiltration that causes base failure and extensive structural damage requiring complete reconstruction.

The timing of repaving maximizes cost efficiency by addressing issues before they escalate into major structural problems. Early intervention preserves the existing base layers, reducing excavation and disposal costs while ensuring optimal performance throughout the driveway’s service life.

What Is the Process for Repaving a Driveway?

The process for repaving a driveway involves systematic assessment, careful preparation, and professional installation techniques. A 2021 PASER (Pavement Surface Evaluation & Rating) study found proper repaving procedures extend driveway life by 12-15 years. The complete process spans preparation, installation, and curing phases.

What Preparation Steps Are Needed Before Repaving Begins?

Preparation steps for repaving begin with PASER scale assessment, which provides standardized evaluation ratings from 0-10. Contractors evaluate five critical factors: color changes indicating UV damage, crack mapping for widths and depths, drainage slope verification at 1.5-3%, foundation stability testing, and maintenance history review.

The assessment includes:

- Visual inspection for color fading from UV exposure

- Crack measurement and location documentation

- Drainage pattern analysis for pooling areas

- Subgrade stability verification

- Review of previous repair records

Existing asphalt removal costs $1-$2 per square foot according to 2023 industry pricing data. This step ensures proper bonding between new and existing materials.

What Should Homeowners Expect During the Repaving Process?

Homeowners should expect systematic overlay application during repaving. A 2022 Madison Municipal case study on 13,333 square yard overlay demonstrated standard procedures: contractors applied 100 tons of leveling course followed by 1,100 tons of surface overlay.

Standard installation specifications include:

- Base layer application at 1.5″ thickness

- Standard asphalt installation at $7-$13 per square foot

- Porous asphalt option at $8-$15 per square foot

- Recycled asphalt alternative at $4-$9 per square foot

Material selection affects both cost and performance. Standard hot-mix asphalt provides durability, while porous options improve drainage.

How Long Does Driveway Repaving Typically Take?

Driveway repaving typically takes 1-3 days depending on size and complexity. Installation timing varies with material choice—Warm Mix Asphalt technology reduces installation time while cutting CO2 emissions by 17-23% compared to traditional methods.

The timeline includes:

- Day 1: Removal and base preparation

- Day 2: Asphalt application and compaction

- Day 3: Curing begins (24-72 hours for light use)

Warm Mix Asphalt extends the paving season by allowing installation at lower temperatures, improving compaction quality. This technology enables repaving during cooler months when traditional hot-mix isn’t viable.

Understanding the repaving process helps homeowners plan effectively for this investment. Next, selecting the right contractor ensures professional execution of these technical requirements.

How Can You Choose the Right Contractor for Repaving Your Driveway?

Choosing the right contractor for repaving your driveway requires evaluating their inspection process, experience, and credentials. A qualified contractor conducts thorough on-site assessments, demonstrates successful project history, and maintains proper licensing and insurance. The selection process determines whether your driveway achieves its expected 12-15 year lifespan or fails prematurely from inadequate installation.

What Questions Should You Ask Before Hiring a Contractor?

The questions you should ask before hiring a contractor focus on their inspection methodology, material expertise, and customer service approach. Essential inquiries cover on-site inspection procedures, drainage evaluation methods, material selection rationale, and reference availability.

A professional contractor performs comprehensive site visits that include drainage assessment, foundation evaluation, and material discussion. The estimate should detail specific measurements, existing damage documentation, and proposed solutions for identified issues. Communication quality during initial consultations indicates future project management effectiveness.

Key estimate elements encompass six critical areas: physical inspection depth, needs assessment thoroughness, drainage problem identification, material option presentation, responsiveness to questions, and verifiable reference provision. Contractors who skip on-site visits or provide vague estimates without addressing drainage and foundation concerns signal potential quality issues.

Request specific information about their drainage evaluation process, as saturation of asphalt layers causes premature driveway failure. Ask how they plan to achieve the required 1.5-3% transverse slope for proper water runoff. These technical questions reveal whether the contractor understands critical factors affecting driveway longevity and can implement solutions that prevent moisture-related failures at longitudinal joints.

How Do You Evaluate Experience and References in Driveway Repaving?

You evaluate experience and references in driveway repaving by examining completed project portfolios, verifying customer testimonials, and assessing technical competency demonstrations. Wolf Paving’s portfolio showcases multiple successful commercial and residential projects that emphasize proper foundation preparation, drainage implementation, and compaction techniques.

The Madison Municipal project exemplifies professional execution standards—completed on budget and schedule with 12-15 year expected durability. This case study involved 13,333 square yards of overlay using 100 tons of leveling course plus 1,100 tons of overlay material. Such detailed project documentation demonstrates a contractor’s capability to handle complex repaving requirements.

Reference verification should include contacting previous clients about project timeline adherence, budget compliance, and long-term performance. Ask references about the contractor’s problem-solving abilities when unexpected issues arose, such as discovering inadequate base material or drainage problems. Quality contractors provide references from projects completed 3-5 years ago, allowing assessment of their work’s durability over time.

Professional contractors maintain documentation of their technical capabilities, including equipment specifications and crew certifications. They should explain their approach to common failure points, particularly moisture damage at longitudinal joints and load-related alligator cracking in wheel paths. Experience with both residential driveways (12-20 year lifespan) and commercial parking lots (10-15 year lifespan) indicates versatility in addressing different project requirements and understanding how usage patterns affect pavement longevity.

Why Is Proper Licensing and Insurance Important for Contractors?

Proper licensing and insurance protect homeowners from financial liability and ensure contractor accountability for quality standards. Licensed contractors meet state-mandated competency requirements and follow industry regulations for asphalt installation. Insurance coverage shields property owners from accident-related lawsuits and provides recourse for substandard workmanship.

Homeowners face legal and financial risk when hiring unlicensed contractors, as property owners remain liable for accidents and injuries occurring on their premises. Insurance verification should include general liability coverage, workers’ compensation, and equipment damage protection. These policies transfer risk from the homeowner to the contractor’s insurance carrier during the repaving process.

State licensing demonstrates a contractor’s knowledge of building codes, environmental regulations, and safety standards. Licensed contractors understand requirements for achieving proper compaction rates, maintaining correct overlay thickness of 1.5 inches, and implementing drainage solutions. They also comply with regulations for recycled asphalt usage and emission standards for Warm Mix Asphalt applications.

Request copies of current license documentation and insurance certificates before signing contracts. Verify coverage amounts meet or exceed project value, typically requiring minimum liability coverage of $1 million. Check license status through state contractor boards to confirm active standing and absence of violations. This verification process protects your investment and ensures the contractor can legally complete your driveway repaving project while maintaining professional standards that result in optimal pavement longevity.

How Should You Approach Driveway Repaving With an Asphalt Coatings Company?

Working with an asphalt coatings company streamlines your driveway repaving project through professional assessment and advanced solutions. A qualified contractor evaluates structural integrity, drainage patterns, and surface conditions using standardized rating systems. Modern asphalt companies offer eco-friendly options such as reclaimed asphalt pavement and permeable surfaces that reduce environmental impact while maintaining durability.

Can Asphalt Coatings Company Help With Deciding When to Repave Your Driveway?

An asphalt coatings company helps decide when to repave your driveway by conducting professional assessments and recommending sustainable solutions. Companies utilize reclaimed asphalt pavement (RAP), which saved 60 million cubic yards of landfill space in 2019 when 97 million tons were reused. A 2022 industry report showed RAP usage reduced CO2 emissions by 2.7 million metric tons nationwide.

Professional contractors install permeable asphalt systems that reduce stormwater runoff and replenish groundwater aquifers. IoT sensors embedded in modern pavements enable real-time traffic and condition monitoring for faster repairs. Self-repairing asphalt contains microcapsules with rejuvenating agents that auto-mend minor cracks. Piezoelectric materials in new pavements convert traffic stress to electricity, powering monitoring systems.

These technological advances help contractors provide data-driven repaving recommendations based on actual pavement conditions rather than estimates.

What Are the Key Takeaways About When to Repave Your Driveway We Covered?

The key takeaways about when to repave your driveway are timing indicators, cost ranges, and size-based pricing structures. Total repaving costs range from $1,400 to $12,100, averaging $6,800 for a typical 600 square foot driveway. Per square foot costs vary from $3 to $15, with average projects costing $4,908 within a range of $2,523 to $7,292.

Size-based estimates provide specific budget guidelines:

- 200 sq ft driveways cost $1,400-$2,800

- 400 sq ft driveways cost $2,800-$5,600

- 600 sq ft driveways cost $4,200-$7,800

- 864 sq ft driveways cost $6,100-$12,100

Full replacement including removal and installation costs $8 to $15 per square foot. Professional assessment determines whether resurfacing at lower costs suffices or complete replacement provides better long-term value.