When you’ve just invested in new asphalt paving, we understand the anticipation of using your freshly paved surface. You’re likely wondering exactly when it’s safe to drive on your new investment without causing damage. We’re here to provide you with expert guidance based on the latest industry standards and research, ensuring your new asphalt surface delivers decades of reliable service.

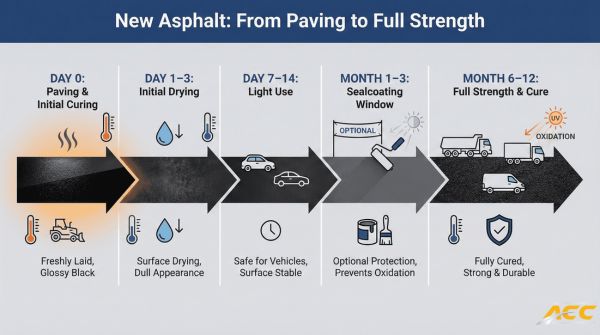

New asphalt is a temperature-sensitive material that requires specific curing conditions before it can safely support vehicle traffic. While initial surface drying occurs within 24-48 hours, the complete curing process extends 6-12 months as the asphalt continues to oxidize and strengthen. According to the New York State Department of Transportation’s 2019 specifications, mix temperatures should remain between 250°F and 325°F during placement, with consistent temperatures being critical for achieving uniform compaction and pavement density.

Dr. Jose Norambuena-Contreras, Senior Lecturer at Swansea University’s Department of Civil Engineering, emphasizes the importance of proper curing: “Creating asphalt that can heal itself will increase durability of roads and reduce need for people to fill in potholes.” This insight from 2025 research highlights how critical the initial curing period is for long-term pavement performance.

Key takeaways from this comprehensive guide include:

• Temperature and weather conditions significantly impact curing times, with optimal conditions being 70-80°F

• Passenger vehicles typically require 48-72 hours wait time, while heavy equipment needs 14+ days

• Visual indicators and professional testing methods can confirm when asphalt is ready for traffic

• Premature use causes permanent damage requiring repairs costing $2-$15 per square foot

• Proper maintenance including sealcoating after 60-90 days extends pavement life by up to 30%

• Professional contractors provide climate-specific recommendations for optimal results

Our exploration reveals that successful new asphalt installation depends on understanding the critical relationship between curing time, weather conditions, and traffic type. We’ll examine the specific factors affecting your asphalt’s readiness, from temperature variations to vehicle weight considerations, ensuring you make informed decisions that protect your investment. This knowledge empowers you to maximize your pavement’s lifespan while avoiding costly premature failures that can result from improper use during the crucial curing period.

Three essential tips for new asphalt success:

• Monitor weather forecasts and plan paving when you’ll have 48+ hours of favorable conditions (above 50°F with low humidity)

• Use visual cues like surface hardness and color changes to gauge curing progress before allowing any traffic

The journey from fresh asphalt installation to a fully cured, traffic-ready surface involves multiple stages and considerations that we’ll explore in detail throughout this guide.

What factors affect the drying and curing time of new asphalt?

The factors affecting asphalt drying and curing time are temperature conditions, mix composition, and environmental variables. The initial set requires 24-72 hours before vehicle traffic. Full curing takes 6-12 months for complete oxidation and strength development. According to the AASHTO Subcommittee for Materials Standards, laboratory curing time is 2-4 hours. Temperature viscosity relationship determines proper mixing and compaction—binder acts as lubricant at mixing temperatures and adhesive at compaction temperatures. Volumetric properties serve as best performance indicators currently available. Understanding these factors helps predict when new asphalt reaches safe driving conditions for different vehicle types and weather scenarios.

How does weather influence asphalt curing time?

Weather influences asphalt curing time through temperature, humidity, and precipitation factors. Optimal curing occurs at 70-80°F with low humidity and sunny conditions. Warm weather above 70°F enables 24-48 hour initial curing. Cold weather below 50°F extends initial curing to approximately one week. Paving is not recommended when ambient or ground temperature falls below 50°F. Below 40°F, asphalt paving should be avoided entirely. High humidity significantly slows curing and extends drying beyond typical 48-72 hours. Cold temperatures cause premature cooling, preventing proper compaction. Weather forecasts must show 48+ hours of favorable conditions after paving for successful installation.

How do asphalt thickness and mix type impact drying time?

Asphalt thickness and mix type impact drying time through material depth and binder characteristics. Minimum lift thickness must be 3 times the nominal maximum aggregate size (NMAS). Maximum lift thickness is 3 inches with static steel-wheeled rollers, 6-8 inches with pneumatic or vibratory rollers. Thicker lifts require longer curing times due to increased material depth. Thinner lifts cure faster with reduced material volume. Performance Graded (PG) binder specifications determine mix performance and curing characteristics. Warm Mix Asphalt (WMA) technologies allow temperature reductions of 50-80°F below conventional HMA. Residential HMA driveways typically consist of 2-inch bottom course with 1.5-inch surface course. Extended high-temperature maintenance during 0-5 hour curing improves rubber-modified asphalt performance.

Why does traffic volume matter for new asphalt readiness?

Traffic volume matters for new asphalt readiness because vehicle weight and frequency determine stress levels on curing pavement. Low-traffic roadways can open sooner than high-traffic roadways. High truck traffic volume requires extended cooling and stiffening time. High-speed traffic needs additional bonding time between asphalt and aggregate. According to NYSDOT specifications, traffic speed must be controlled to 20 mph or less on tacked areas. Slow-moving traffic on new seal coat after final rolling reduces premature aggregate loss. Traffic restriction continues until emulsion completely breaks. Fresh mat requires cooling to specified temperature before traffic access. Heavy traffic loads applied prematurely cause permanent deformation and structural damage requiring costly repairs.

What is the recommended waiting time for cars versus heavy vehicles on new asphalt?

The recommended waiting time for cars versus heavy vehicles on new asphalt varies significantly based on vehicle weight. Passenger vehicles require 48-72 hours minimum before driving, while heavy vehicles need at least 14 days. These different timelines reflect the impact of weight distribution on curing asphalt surfaces.

How soon after paving can you drive a passenger vehicle?

Passenger vehicles can drive on new asphalt after a minimum wait time of 48-72 hours. This three-day period allows initial surface hardening while the asphalt continues its curing process.

Foot traffic is typically allowed within 24 hours of paving. Light vehicle traffic can begin after 48-72 hours at controlled speeds. Passenger cars distribute less weight per square inch than heavy vehicles, making them safer for early use.

The initial 24-48 hour period should remain limited to foot traffic and essential light vehicles only. Vehicles traveling on newly paved surfaces during the 48-72 hour window must maintain reduced speeds. This controlled approach prevents surface damage while the asphalt develops its initial strength.

When is it safe for trucks and RVs to use newly paved asphalt?

Trucks and RVs require a minimum wait time of 14+ days before using newly paved asphalt. Heavy equipment should wait the same 14+ day period to prevent structural damage.

Heavy vehicles cause permanent indentations when driven on incompletely cured asphalt. The concentrated weight of heavy equipment damages asphalt that hasn’t fully hardened. Commercial vehicles need this extended curing time compared to passenger cars due to their significantly higher axle loads.

Truck traffic restrictions should remain in place for the full two-week period after paving. Parking heavy vehicles on new asphalt should be avoided for at least 14 days. Weight concentration in wheelpaths from heavy vehicles accelerates pavement damage when the surface isn’t fully cured.

These waiting periods ensure your new asphalt surface develops adequate strength to handle different vehicle types without sustaining damage that would require costly repairs.

How can you tell if new asphalt is ready for traffic?

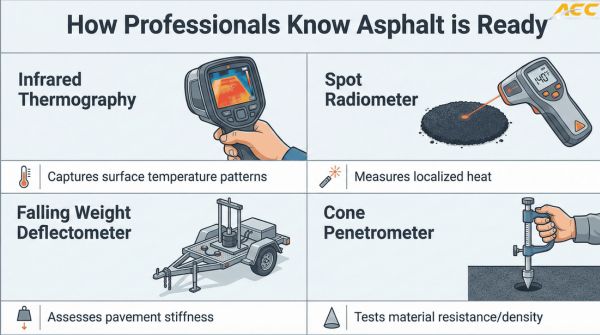

New asphalt readiness for traffic depends on visible curing indicators and professional testing methods. Surface hardness and thermal properties reveal curing progress within 24-48 hours, while specialized tools provide precise measurements for safe traffic resumption.

What visual signs indicate asphalt is cured enough for driving?

Asphalt cured enough for driving displays a hard, tacky surface when touched, indicating the emulsion has broken. Surface drying becomes visible within 24-48 hours, though full curing requires 7-10 days for complete cure. Asphalt cement stiffens sooner than asphalt emulsions, creating different readiness timelines.

Thermal variations signal curing differences across the pavement surface. During daytime, defects appear as hot spots on cooler pavement. During nighttime, defects appear as cold spots on warmer pavement. These temperature contrasts occur because defective areas have different thermal properties than surrounding sound material.

Visual inspection reveals surface readiness through color changes and texture uniformity. Properly cured asphalt maintains a consistent appearance without soft spots or depressions.

Are there any tests or tools to check asphalt readiness?

Infrared thermography detects thermal segregation defects during asphalt paving construction through wavelengths 0.7-14 micrometers. Professional contractors use multiple testing methods to verify pavement readiness:

| Technology | Function | Configuration | Measurement |

| Infrared Bar Sensors | Real-time surface temperature control | Paver-mounted | Continuous thermal monitoring |

| Thermal Cameras | Asphalt surface heat profiling | Stationary or vehicle-mounted | Thermal imaging over area |

| Spot Radiometers | Precise point temperature checks | Handheld or mounted | 250°F–325°F optimal during placement |

| Falling Weight Deflectometer (FWD) | Assess pavement load response | Portable testing unit | Indicates structural soundness |

| Dynamic Cone Penetrometer (DCP) | Evaluate subgrade stability | Manual or automated device | Reveals section strength and uniformity |

| Indirect Tensile Strength (IDT) Test | Analyze asphalt mix integrity | Laboratory-based | Measures HMAC density and strength variation |

These tools provide contractors with immediate feedback about pavement quality and curing status, ensuring traffic resumes only when asphalt achieves adequate strength.

What can happen if you drive on new asphalt too early?

Driving on new asphalt before proper curing causes permanent structural damage that significantly reduces pavement lifespan. Premature traffic exposure creates deformation patterns that compromise the asphalt’s integrity and lead to accelerated deterioration requiring expensive repairs.

How does early driving damage new asphalt?

Early driving damages new asphalt through rutting and permanent deformation when heavy vehicles create indentations in inadequately cured surfaces. Premature loading causes segregated asphalt that resists proper compaction, resulting in lower density areas with increased air voids and permeability.

Top-down cracking occurs within three years of construction from premature loading. Fatigue cracking develops interconnected patterns from repeated traffic loads on incompletely cured asphalt. There are multiple failure modes, such as raveling that causes aggregate loss, pothole formation, and stripping where adhesion fails between layers.

Poor bonding between overlays and substrate layers causes premature cracking throughout the pavement structure. These damage mechanisms compound over time, transforming minor surface issues into major structural failures requiring complete reconstruction.

What repairs or remedies are needed if the surface is used too soon?

Repairs for prematurely damaged asphalt range from crack repair at $2-$5 per square foot to full replacement at $8-$15 per square foot. Extensive base failure requires milling and overlay at $5-$8 per square foot, totaling $25,000-$40,000 for a 5,000 square foot area.

Pothole repairs cost significantly more than filling small cracks initially. Ignoring small cracks leads to repair bills exceeding $5,000 within a few years as damage spreads. Premature failure reduces pavement design life by years or decades through cumulative damage.

Inadequate curing allows water infiltration causing moisture damage throughout the pavement structure. Early traffic exposure creates a cascade of failures requiring increasingly expensive interventions that could have been prevented by following proper curing protocols.

What best practices should you follow after fresh asphalt paving?

Following proper protocols after fresh asphalt paving determines whether your pavement lasts 20 years or fails within 5 years. New asphalt requires specific protection measures during its critical curing period to develop full strength and durability. The following practices ensure your investment performs as designed.

How can you protect new asphalt until it fully cures?

Protecting new asphalt until it fully cures requires keeping all traffic off emulsion surfaces until complete curing occurs. Apply sand cover in cold weather conditions below 50°F to prevent surface damage. Implement traffic maintenance protocols immediately after emulsion breaks and paving begins, using pilot vehicles to maintain speeds below 20 mph.

Essential protection measures include:

- Schedule paving only during favorable weather (above 50°F, dry conditions)

- Deliver and place HMA at proper temperatures (250°F-325°F)

- Use machine placement instead of hand work for uniform density

- Complete rolling and compaction with calibrated equipment

- Apply weed killer to prevent vegetation penetration through new sections

Cold or rainy conditions compromise asphalt bonding and compaction quality. Machine placement achieves 15% better density uniformity than hand work. Proper rolling techniques prevent segregation and ensure 92-96% target density. These protection measures directly impact whether your pavement achieves its 20-year design life or requires premature repairs costing $5-$8 per square foot.

When should you consider sealcoating newly paved asphalt?

The optimal time to sealcoat newly paved asphalt is 90 days to 6 months after installation. New pavement requires 60-90 days minimum before accepting any sealcoat application. Some contractors recommend waiting 6-12 months for maximum pavement strength development before the first sealcoat.

Temperature and weather requirements for sealcoating include:

- Minimum 50°F surface temperature during application

- Temperature must remain above 50°F for 48 hours post-application

- Sunny, dry conditions required for 48 hours after application

| Category | Attribute | Optimized Value / Requirement |

| First Sealcoat Timing | Minimum Wait Period | 60–90 days after new asphalt installation |

| First Sealcoat Timing | Optimal Application Window | 90 days to 6 months post-paving |

| First Sealcoat Timing | Extended Wait (Contractor Advice) | 6–12 months for full pavement strength |

| Residential Driveways | Recommended Reseal Frequency | Every 2–3 years |

| Commercial Lots | Recommended Reseal Frequency | Every 1–2 years |

Apply your first sealcoat within one year of installation to protect against oxidation and moisture infiltration. Longer initial waiting periods produce stronger pavement bonds before sealing. Residential driveways need resealing every 2-3 years, while commercial lots require resealing every 1-2 years due to heavier traffic loads. These maintenance intervals extend pavement life by up to 30% compared to unsealed surfaces.

How does proper timing of usage extend the lifespan of new asphalt?

Proper timing of usage extends the lifespan of new asphalt by allowing complete binder oxidation and aggregate bonding before traffic exposure. According to a 2019 study by the National Center for Asphalt Technology, premature traffic opening reduces pavement design life by up to 40%. Waiting the recommended curing period ensures optimal stiffness development and prevents early structural damage.

What maintenance tips help keep fresh asphalt in good condition?

The maintenance tips that help keep fresh asphalt in good condition are regular inspection, timely crack sealing, and periodic sealcoating. A 2020 Federal Highway Administration report found that proper maintenance extends pavement life by up to 30%. Sealcoating costs significantly less than full repaving while preventing water infiltration.

Early intervention prevents exponential cost increases. Regular inspections catch small cracks before they become potholes. Well-designed driveways provide trouble-free service for up to 20 years with proper maintenance. Asphalt pavement lasts 25 years when properly maintained versus 10-15 years when neglected.

Key maintenance procedures include:

- Annual visual inspections for cracks and surface deterioration

- Crack sealing within 6 months of detection

- Sealcoating every 2-3 years for residential driveways

- Prompt pothole repairs to prevent base damage

Neglecting maintenance leads to critical issues requiring full replacement at $8-$15 per square foot versus $2-$5 for crack repairs.

How does delayed use affect asphalt resilience and appearance?

Delayed use affects asphalt resilience and appearance by allowing complete binder hardening and improved rutting resistance. A 2018 Transportation Research Board study on cold-recycled mixtures showed 67.2-100% stiffness increase after 7-day curing periods. Proper curing during production remains vital for mix design success.

Temperature and weather conditions affect bonding quality during the curing phase. Longer curing improves rutting resistance for both HMA and WMA mixes. Asphalt binders from prematurely loaded sections show higher complex shear modulus, indicating stiffer but more brittle material.

High variability in tensile strength is associated with premature cracking patterns. Cracking from premature loading provides pathways for water ingress, accelerating deterioration. The curing process allows binder oxidation and hardening before traffic exposure, creating a more resilient surface that maintains its appearance longer.

Proper timing ensures uniform strength development across the pavement surface, preventing weak spots that lead to premature failure and unsightly surface defects.

What should you ask your paving contractor about using new asphalt?

When planning new asphalt installation, asking your contractor the right questions ensures proper curing and longevity. Your contractor should provide specific timelines for vehicle use and climate-adapted instructions that protect your investment.

What timeline does your contractor recommend for driving and parking?

Your contractor’s recommended timeline for driving and parking depends on mix temperature specifications and verification procedures. Contractors must notify HMA manufacturers of intended paving operations one day prior to paving. The specified temperature range between 250°F and 325°F requires confirmation at pre-pave meetings. Consistent mix temperatures achieve uniform compaction and pavement density.

Job Mix Formula verification procedures determine specific mix recommendations for driveway applications. Established, reputable producers must provide the asphalt mix. A base course of 6-8 inches of crushed aggregate proves typically adequate for residential driveways. Mix temperature discussions during pre-pave meetings establish critical parameters for successful installation.

Understanding these timelines helps property owners plan vehicle access and protect new pavement during the crucial initial curing period.

Are there specific instructions for your climate or site conditions?

Specific instructions for your climate or site conditions vary significantly by region. Cold climates require extended curing times of approximately one week before vehicle traffic. Hot and arid climates allow faster curing but risk premature hardening without proper moisture control. High humidity regions need slower curing and longer traffic restrictions to prevent damage.

Cool temperatures require longer curing times prior to opening roadways to traffic. Humidity greater than 50% significantly extends curing time for all asphalt types. There are three critical moisture-related factors: emulsions require more time to break in high humidity, rain on emulsions causes aggregate and binder loss, and waiting several months before driveway installation after backfill often proves beneficial.

Subgrade preparation remains essential regardless of climate. The subgrade should be graded smooth and made free of organic materials before paving begins.

These climate-specific instructions from your contractor ensure optimal curing conditions and prevent premature failure of your new asphalt surface.

How can Asphalt Coatings Company help you care for new asphalt surfaces?

Asphalt Coatings Company provides specialized paving and aftercare services that ensure your new asphalt surfaces cure properly and last longer. The company offers nighttime construction without the lengthy curing delays of concrete, plus flexible scheduling that adapts to your traffic needs. Their quality control systems detect thermal segregation and density problems during paving, preventing premature failure before the pavement cures.

What asphalt paving and aftercare services does Asphalt Coatings Company offer?

Asphalt Coatings Company offers nighttime construction that eliminates the extended curing time required for concrete pavements. The company provides flexible scheduling options and real-time thermal segregation detection during paving operations. Their infrared bar sensors mount directly on pavers to monitor asphalt density uniformity across the full mat width. This technology detects lower-density areas susceptible to premature failure before the pavement cures. The system provides immediate operator feedback, allowing crews to correct inadequate density issues during construction rather than after problems develop.

What are the main points to remember about when to drive on new asphalt?

The main points to remember are that asphalt pavements can open to traffic once compacted and cooled, but full strength requires an extended curing period. There’s a critical distinction between initial traffic readiness and complete curing—opening too early reduces pavement life significantly. Industry standards recommend conservative waiting periods of 48-72 hours for cars and 14+ days for heavy vehicles. Success depends on three factors: good design, good materials, and good construction practices. Temperature directly affects compaction quality, rolling patterns, and paving speed throughout the process. Proper subgrade preparation provides the essential foundation, while correct line and grade ensure long-term performance.