A professional asphalt paving proposal is a comprehensive document that outlines every critical aspect of your paving project, from material specifications to payment terms, serving as both a roadmap for successful project execution and a legal safeguard for all parties involved. Whether you’re a property owner seeking asphalt services or a contractor preparing proposals, understanding what makes a thorough paving proposal can mean the difference between a smooth project and costly disputes.

According to the National Asphalt Pavement Association (NAPA), the U.S. has 2.7 million miles of paved roads with 94% surfaced with asphalt, representing a $30 billion annual industry employing over 400,000 Americans. In 2022, AIA Contract Documents analyzed 892,457 change orders from 18,229 completed projects, finding that 38.24% of construction projects have only one change order, while some experience up to 25% in change order costs.

As NAPA President & CEO Audrey Copeland, Ph.D., P.E. states: “Our experts – members, staff, research partners, and others – will continue to employ the best science, safety practices, fiduciary responsibility, and environmental stewardship to connect communities and keep America moving.”

Key takeaways from our comprehensive guide include: Understanding why detailed proposals prevent 36.9% of disputes caused by scope changes; Essential project scope details including site specifications and ADA compliance requirements; Material specifications with costs ranging $100-$200 per ton for hot-mix asphalt; Cost breakdowns and payment terms with typical 10-50% deposits; Warranty coverage standards of 1-5 years for private sector projects; Insurance requirements averaging $5,000+ annually for comprehensive coverage; Critical documentation including drawings and reference portfolios; Red flags to watch for when evaluating contractor proposals.

Our analysis reveals these universally applicable insights: A well-crafted proposal builds trust through clear documentation that helps projects stay on schedule and within budget while ensuring participant satisfaction. Industry best practices show that 1% increase in density extends pavement life by at least 10%, making proper specifications crucial for long-term value.

We’ve explored how professional asphalt paving proposals serve as the foundation for successful projects, examining everything from technical specifications to legal protections, ensuring you have the knowledge to either create or evaluate proposals that protect your interests and deliver quality results.

Why Is a Detailed Asphalt Paving Proposal Important?

A detailed asphalt paving proposal is important because it prevents costly disputes, change orders, and project delays through comprehensive documentation. Construction projects without proper proposals face significant risks, such as scope changes accounting for 36.9% of disputes globally and change order costs reaching up to 25% of project value.

What Risks Can Occur Without a Comprehensive Proposal?

The risks that can occur without a comprehensive proposal include change orders, disputes, and design errors that derail construction projects. A 2024 construction industry analysis reveals that 38.24% of projects experience at least one change order, with some facing up to 25% in additional costs. Change in scope causes 36.9% of global project disputes (25.7% in the Americas). The average value of North American construction disputes increased 40% in 2024. Design errors account for 21.5% of disputes, while late design information causes another 21.4%.

How Does a Well-Crafted Proposal Build Trust and Transparency?

A well-crafted proposal builds trust and transparency by clearly documenting scope, expectations, and responsibilities, which leads to smoother project execution. Proper documentation keeps projects on schedule and within budget through precise scope definition. Version control ensures all team members work from the latest documents, eliminating confusion. Well-documented proposals meet safety and quality standards while ensuring participant satisfaction. Clear expectations reduce misunderstandings between contractors and clients, creating accountability throughout the project lifecycle.

The following sections detail essential components that transform basic quotes into comprehensive asphalt paving proposals that protect both parties and ensure successful project completion.

What Essential Project Scope Details Must Be in an Asphalt Paving Proposal?

The essential project scope details that must be included in an asphalt paving proposal are site location specifications, service descriptions, and timeline milestones. Professional proposals document every aspect from preparation through completion. Clear scope definition prevents disputes and ensures project success.

What Information Should Be Provided About Site Location and Layout?

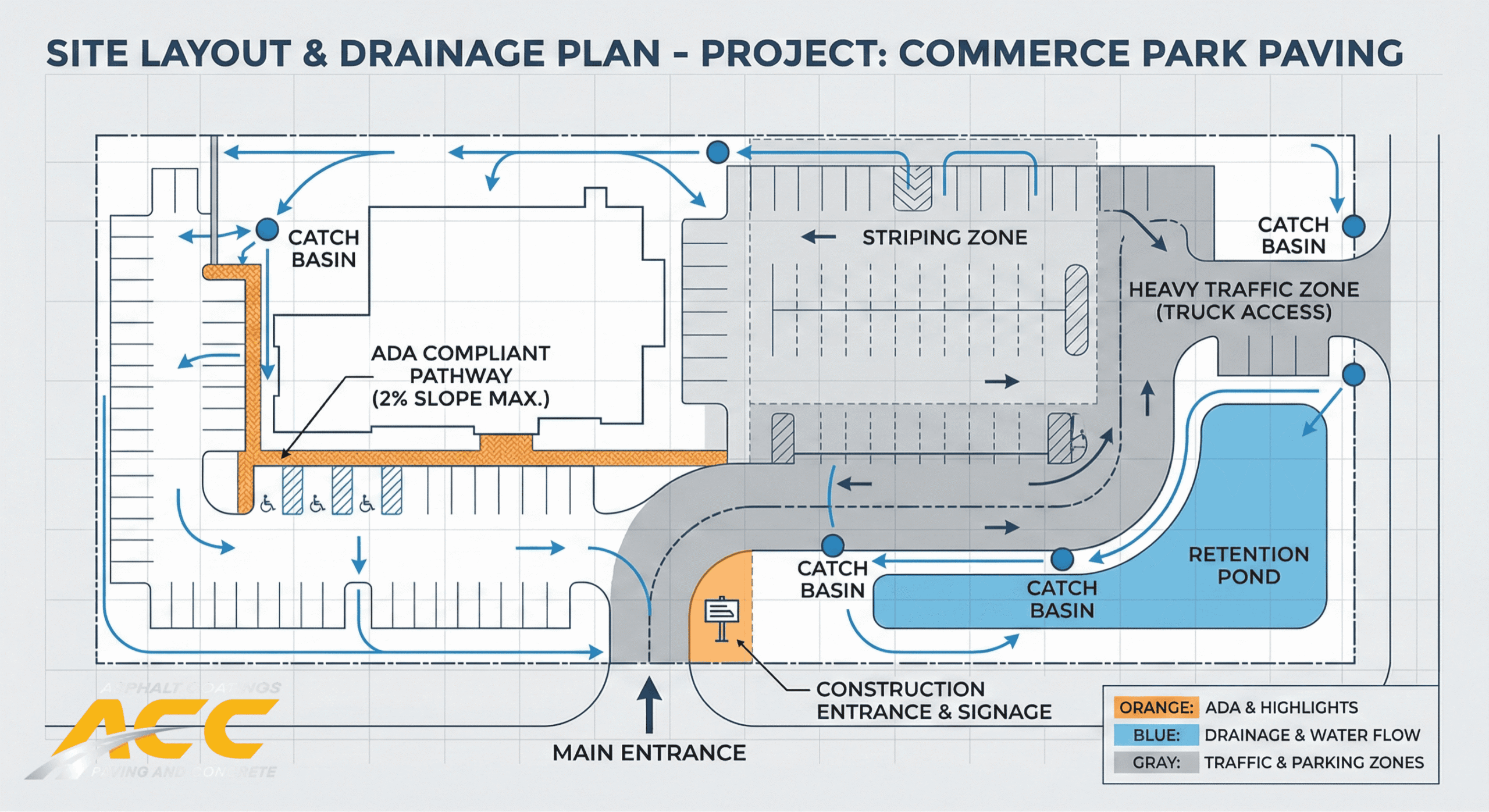

Information provided about site location and layout should include preparation requirements, accessibility compliance, and drainage specifications. Site preparation encompasses cleanup, base layer installation, asphalt application, striping, and markings. Commercial projects require ADA-compliant pathways with maximum 2% slope for accessible routes.

Loading zones need specific traffic flow patterns for commercial properties. Drainage work requires documented grading and leveling requirements. Each site element affects material quantities and labor hours.

What Types of Work or Services Should Be Clearly Outlined?

The types of work or services that should be clearly outlined in an asphalt paving proposal include preparation, paving, and finishing operations. The U.S. maintains 2.7 million miles of paved roads with 94% surfaced using asphalt. There are 3,500 asphalt plants operating nationwide with at least one in every congressional district.

Annual U.S. asphalt production reaches 400 million tons valued at $30 billion. The industry employs 400,000+ Americans across asphalt production, aggregate production, and road construction sectors. Service descriptions must specify material types, application methods, and quality standards.

How Should Timelines and Milestones Be Communicated?

Timelines and milestones should be communicated by using phase-specific schedules with clearly defined deliverables. The planning phase typically requires 2-4 weeks for permits and materials ordering. Site preparation takes 1-2 weeks including excavation and grading operations.

Paving phase ranges from days to weeks depending on project size and complexity. Weather delay provisions protect both parties from unforeseen scheduling impacts. Consequences for missed deadlines ensure accountability throughout the project timeline.

These scope details form the foundation of any professional asphalt paving proposal, establishing clear expectations for successful project execution.

Which Material Specifications and Techniques Should Be Included?

The material specifications and techniques that should be included in an asphalt paving proposal define the technical foundation that determines pavement performance and longevity. The asphalt mixture quality and construction methods directly determine pavement longevity and performance.

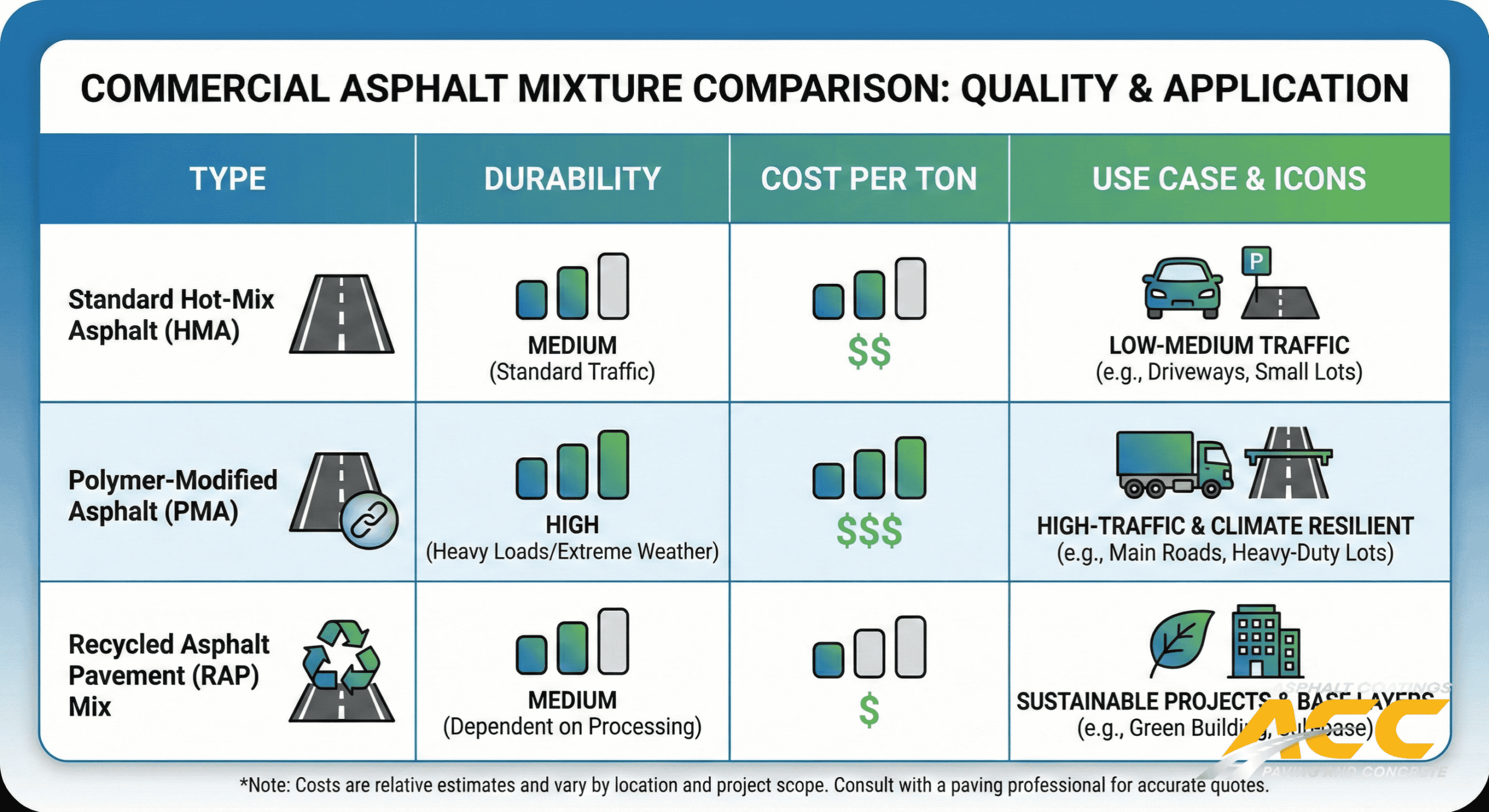

How Should Asphalt Mixtures and Quality Standards Be Described?

Asphalt mixtures and quality standards should be described by clearly defining material composition, binder content, mix types, temperature requirements, and performance criteria. Hot-mix asphalt costs $100-$200 per ton nationally in 2025. Premium Hot-Mix ranges $150-$200 per ton, while Standard Hot-Mix costs $100-$150 per ton.

Polymer-Modified asphalt costs $150-$220 per ton and provides enhanced durability for high-traffic areas. Recycled asphalt (RAP) costs $10-$20 per ton with the U.S. recycling rate exceeding 80%. The minimum placement temperature is 175°F, though this varies by mix type. Asphalt production temperature ranges 275-350°F for proper workability.

Quality standards must specify exact mix designs, aggregate gradations, and binder grades for your project. Temperature requirements ensure proper compaction and bonding between layers.

What Construction Methods and Best Practices Need to Be Listed?

The construction methods and best practices that need to be listed include minimum lift thickness requirements, spread rates, compaction density targets, and surface smoothness tolerances. Standard spread rate is 110 lbs per square yard per inch of thickness. Compaction density requirement ranges 92-96%, with 92-93% immediately after construction and 96% over time.

| Construction Element | Performance Attribute | Required Standard / Impact |

| New lift | Smoothness improvement | 50% average |

| Density increase | Pavement life extension | 10% minimum per 1% density |

| Surface smoothness | Maximum deviation | 1/4 inch over 10 feet |

| Lift thickness | Minimum requirement | 4x NMAS |

| Spread rate | Standard application | 110 lbs/sq yd/inch |

Construction methods must detail equipment specifications, paving sequences, and joint construction procedures. Quality control testing protocols ensure specifications are met throughout the project.

What Are the Key Cost and Payment Terms to Disclose in a Proposal?

The key cost and payment terms that should be disclosed in an asphalt paving proposal include itemized estimates with unit pricing, structured payment schedules, and change order provisions. Clear financial transparency prevents disputes and establishes mutual expectations before work begins.

How Should Estimates, Unit Pricing, and Allowances Be Presented?

Estimates, unit pricing, and allowances should be presented using clear line-item breakdowns that show material costs, labor rates, and total installed prices per square foot. Total installed asphalt paving costs average $7-$13 per square foot nationally. Labor costs range $2-$6 per square foot depending on project complexity and local market rates.

General contracting work costs $40-$55 per hour for standard paving operations. A 2025 industry analysis shows national average driveway installation costs approximately $5,000, with typical ranges between $4,000-$8,000. Asphalt material only costs $5-$7 per square foot before installation.

Transportation adds $0.15-$0.25 per ton-mile to total project costs. Contractors should itemize these charges separately to maintain pricing transparency.

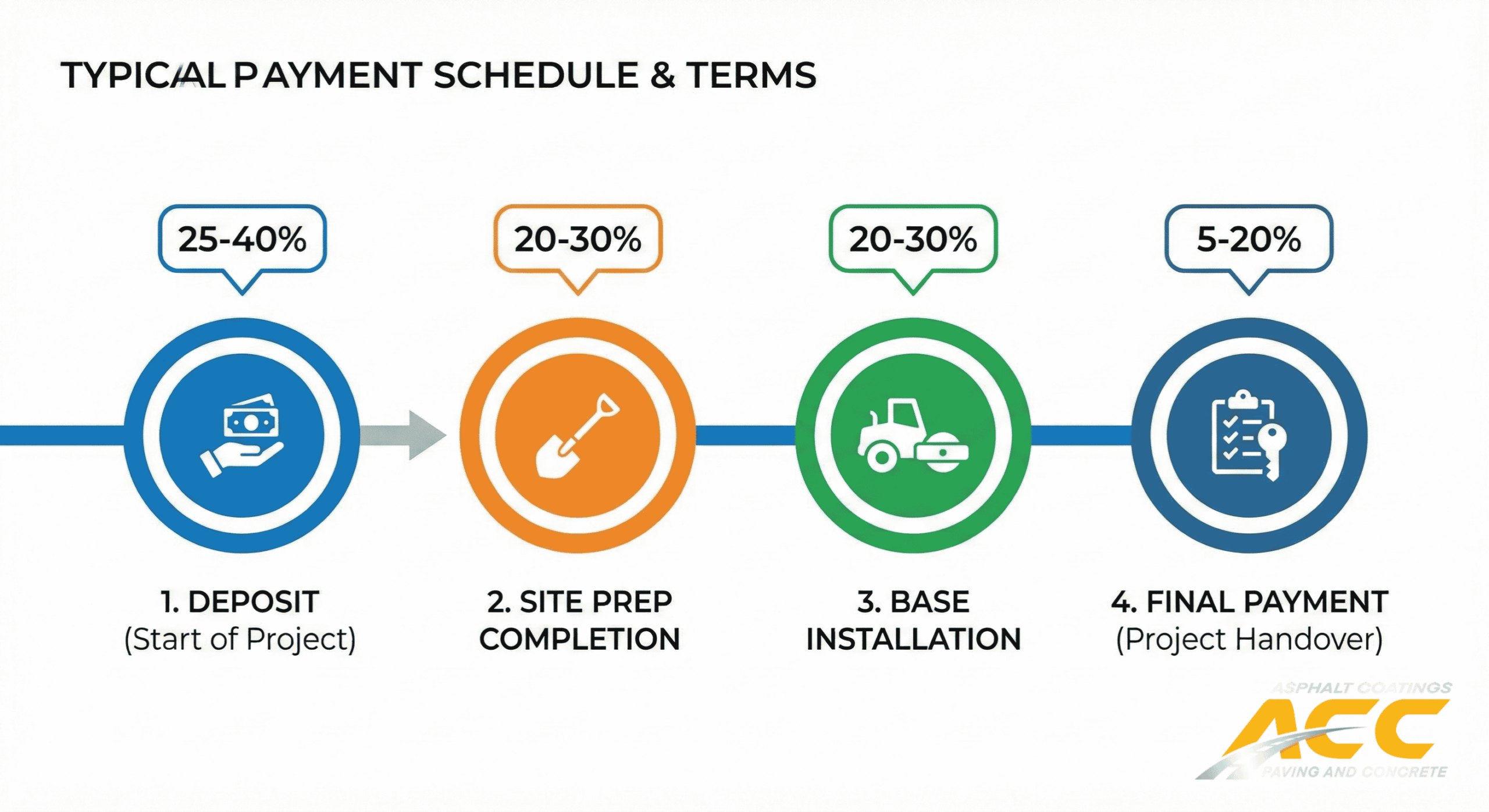

What Payment Schedule and Terms Should Be Outlined?

The payment schedule and terms that should be outlined in a paving proposal include specific payment percentages tied to project milestones and completion stages. Typical deposits range 10-20% for larger projects and 25-50% for smaller projects. Progress payments in 25-35% increments align with construction phases.

There are standard payment structures such as 10-50% deposit, 25-35% after site preparation, 25-35% after base installation, and remaining balance upon completion. Never pay the full amount upfront regardless of project size or contractor reputation.

Are There Provisions for Potential Extra Costs or Change Orders?

Yes. Provisions for potential extra costs or change orders are essential contract components that protect both parties from unforeseen circumstances. Change orders account for 10-15% of contract value on major projects according to construction industry data. Price change clauses should specify a 10% trigger threshold, though some jurisdictions require 5%.

A 15-20% cap on increases represents typical industry practice, while federal projects may allow ±50% variation. Notice periods of 7-30 days for price changes give clients time to evaluate alternatives. Written change order requirements and approval processes must be documented before work proceeds.

Clear cost disclosure and payment terms create the foundation for successful project completion while the next section on warranties and maintenance responsibilities defines long-term expectations after installation.

How Should Warranties and Maintenance Responsibilities Be Addressed?

Warranties and maintenance responsibilities should be addressed by clearly defining coverage periods, performance criteria, and required maintenance practices within the asphalt paving proposal. Industry standard warranties range from 1-5 years for private sector projects, with specific coverage periods varying by project type. Clear maintenance guidelines ensure asphalt surfaces achieve their expected 15-25 year lifespan through proper care.

What Warranty Details Are Typical for Asphalt Paving Projects?

The warranty details that are typical for asphalt paving projects include coverage periods ranging from 1–5 years for private sector work. Full depth asphalt replacement projects commonly carry 3-5 year warranties, while milling and overlay work typically includes 1 year coverage. Materials and workmanship warranties extend 2-4 years, covering defects within the contractor’s control such as improper installation or material mixing errors.

Short-term performance warranties span 5-10 years and include specific pavement performance criteria like surface smoothness and structural integrity. Long-term performance warranties extend 10-20 years, with European countries implementing 11-20 year warranty periods as standard practice. These extended warranties demonstrate contractor confidence in their materials and installation methods.

How Are Maintenance Guidelines and Client Obligations Defined?

Maintenance guidelines and client obligations are defined through specific service intervals and cost estimates for routine care. Sealcoating is required every 2-3 years at approximately $500 per application to protect the asphalt surface from UV damage and water infiltration. Crack filling costs $1-$3 per linear foot and prevents water penetration that causes base deterioration.

Pothole repair ranges $2-$4 per square foot depending on depth and extent of damage. Complete resurfacing costs $3-$7 per square foot when the existing surface becomes too degraded for spot repairs. Quality asphalt surfaces last 15-25 years or more with proper maintenance, making regular care a cost-effective investment compared to premature replacement.

Proper maintenance scheduling and client compliance with recommended service intervals directly impact warranty validity and pavement longevity. Understanding these responsibilities helps property owners budget for long-term asphalt care while maximizing their initial paving investment.

What Legal, Insurance, and Compliance Elements Belong in a Proposal?

The legal, insurance, and compliance elements that belong in an asphalt paving proposal include contractor licenses, insurance coverage documentation, and local permit requirements. These components protect both parties and ensure regulatory compliance throughout the project.

What Licenses and Certifications Should Be Documented?

The licenses and certifications that should be documented in an asphalt paving proposal vary by state and jurisdiction. California requires contractors to obtain a C-12 license from the Contractors State License Board with a $25,000 license bond. Texas contractor registration varies by municipality, with larger cities demanding higher liability limits than smaller jurisdictions.

Nebraska requires Department of Labor registration and workers’ compensation certificate for contractors with one or more employees. The National Asphalt Pavement Association (NAPA) represents 1,100 member companies since 1955, providing industry certification standards.

State-specific licensing requirements must be verified before contract signing. Documentation should include license numbers, expiration dates, and bond verification details.

How Are Insurance Coverage and Liability Requirements Explained?

Insurance coverage and liability requirements are explained by clearly outlining policy types, coverage limits, and associated monthly or annual costs. General Liability insurance averages $77 per month with typical limits of $1M per occurrence and $2M aggregate. Workers’ Compensation costs average $260 per month and remains required in most states.

Commercial Auto insurance averages $173 per month for dump trucks and equipment haulers. Tools & Equipment coverage, also known as Inland Marine insurance, costs $14 per month. Business Owner’s Policy (BOP) averages $172 per month, bundling general liability and property coverage.

Small paving contractors pay starting at $5,000 annually for comprehensive insurance packages. These coverage details demonstrate financial responsibility and risk management capabilities.

What Local Codes or Permits Might Affect the Work?

The local codes or permits that might affect asphalt paving work include municipality-specific regulations and ADA compliance standards. Local municipality permits vary by jurisdiction, requiring contractors to research specific area regulations. ADA requirements mandate proper curb ramps and detectable warning surfaces for commercial projects.

Accessible routes in commercial projects require a maximum 2% slope. Thickness requirements differ by application type:

| Application Type | Required Thickness | Purpose |

| Residential driveways | 2-3 inches | Light vehicle traffic |

| Light commercial parking | 3-4 inches | Standard vehicle loads |

| Heavy commercial traffic | 4-6 inches | Frequent truck traffic |

| Loading docks | 6-8 inches | Heavy equipment zones |

Understanding these requirements ensures proposals meet all regulatory standards and avoid costly project delays or modifications.

What Additional Documentation or References Should Accompany an Asphalt Paving Proposal?

The additional documentation or references that should accompany an asphalt paving proposal transform a basic estimate into a comprehensive project blueprint. Supporting materials provide visual clarity, establish credibility, and create transparent expectations between contractors and clients.

Which Drawings, Maps, or Photographs Enhance Clarity?

The drawings, maps, and photographs that enhance clarity in an asphalt paving proposal include site layout plans, traffic control diagrams, drainage plans, and before-and-after project images. These plans illustrate temporary barriers, signage placement, and pedestrian routing during construction phases.

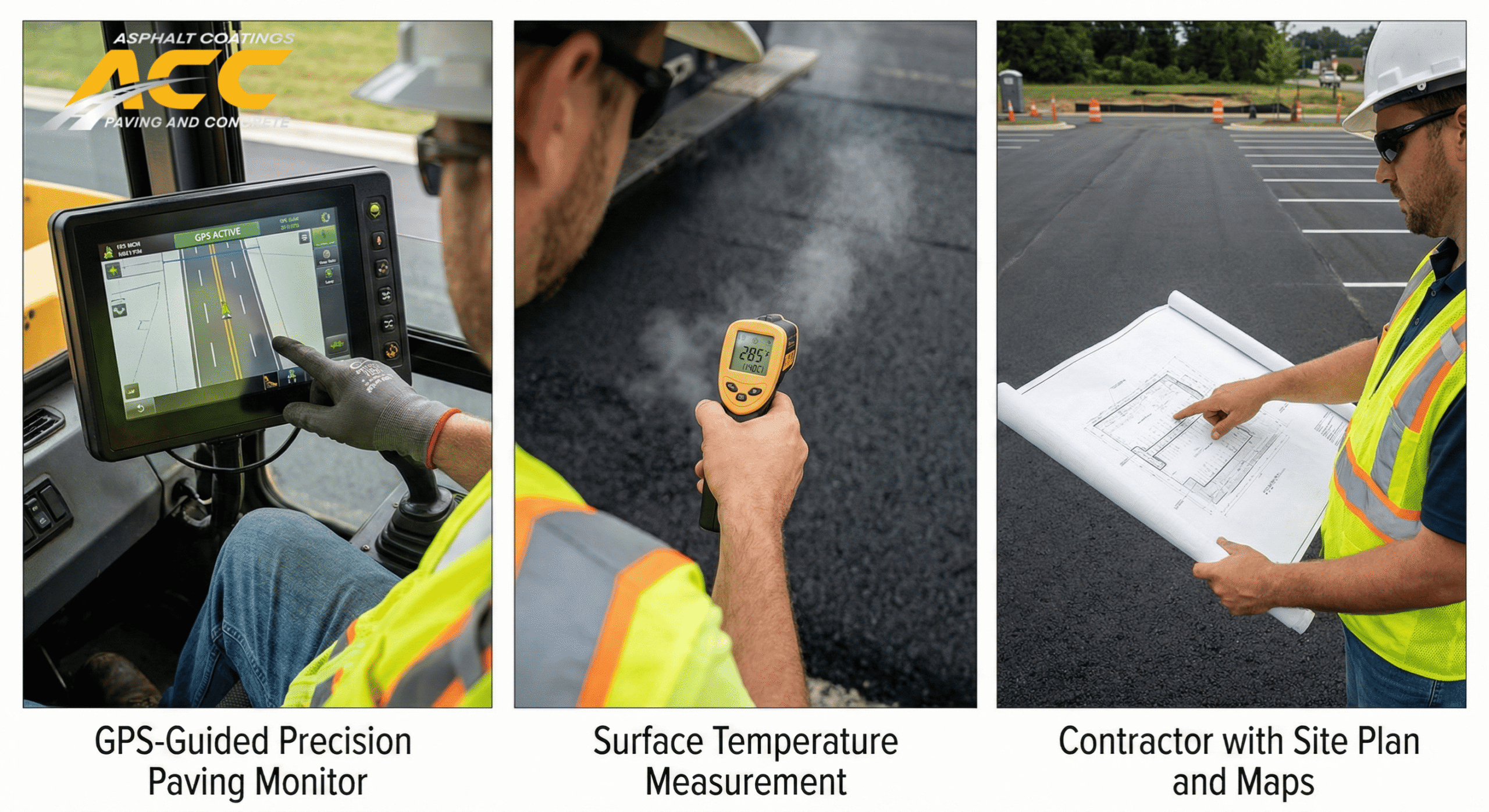

Drainage plans and grading specifications demonstrate water management strategies. There are multiple drainage solutions such as crown slopes, cross-slopes, and catch basins. GPS-guided paving data ensures consistent mat thickness and smoother grades across the entire project surface.

Temperature monitoring documentation validates quality control procedures. Asphalt placement requires minimum surface temperatures of 50°F, with material temperatures between 275-350°F for optimal workability. Visual documentation confirms adherence to these critical temperature requirements throughout the paving process.

Before-and-after photographs from similar projects showcase contractor capabilities. These visual references help clients understand expected outcomes and surface finish quality.

Are Client References or Past Project Case Studies Advantageous?

Yes. Client references and past project case studies are advantageous because they demonstrate contractor reliability through verified project completion records. A 2020 analysis of 892,457 change orders from 18,229 completed projects provides industry performance benchmarks for proposal evaluation.

Portfolio documentation shows experience levels across different project scales. Projects valued $1-5M represent 33.61% of the asphalt paving market, while $0-500K projects account for 20.86% of industry volume.

Case studies highlighting similar scope projects provide concrete examples of problem-solving abilities. There are many project challenges such as weather delays, subsurface issues, and traffic management that case studies can address.

Written testimonials and contact information for reference checks strengthen proposal credibility. Performance metrics from past projects, including on-time completion rates and budget adherence percentages, quantify contractor reliability.

This comprehensive documentation package creates transparency and builds client confidence in the proposed asphalt paving project.

How Should You Evaluate an Asphalt Paving Proposal Before Accepting?

You should evaluate an asphalt paving proposal before accepting it by systematically reviewing contractor qualifications, technical specifications, and contractual protections. The U.S. produces 400 million tons of asphalt annually across 3,500 plants, making contractor selection critical for project success. Your evaluation should focus on verifying experience, identifying warning signs, and ensuring comprehensive documentation before signing any agreement.

What Questions Should You Ask About the Contractor’s Experience?

The questions you should ask about a contractor’s experience focus on their ability to deliver quality work that ensures long-term pavement performance. Verify the contractor regularly handles projects within the 400 million tons of asphalt produced annually in the U.S. market. Confirm their experience with appropriate thickness standards, such as 2-3 inches for residential driveways or 6-8 inches for loading docks.

Ask about nuclear density gauge testing capabilities, as proper compaction must average 98% of control strip density. According to a 2023 industry study on warm mix asphalt adoption, this technology is growing at 15% annually. Inquire whether the contractor uses intelligent compaction systems for real-time density and temperature monitoring during placement.

Request specific examples of similar projects completed within your region. Contractors should demonstrate familiarity with local permit requirements and ADA compliance standards, including 2% maximum slope for accessible routes.

What Red Flags Should You Watch for in a Proposal Review?

The red flags you should watch for in a proposal review include missing insurance certificates, vague specifications, and absent quality control requirements. General liability coverage below $1-2 million fails to meet industry minimums established by major municipalities. A 2024 construction insurance study found that adequate coverage averages $77 monthly for $1 million per occurrence.

Absence of weather delay provisions creates project risk, as surface temperatures must exceed 50°F for proper asphalt placement. Proposals lacking specific density requirements between 92-96% or omitting testing protocols indicate substandard quality control measures.

Watch for missing written change order procedures, which according to a 2024 North American construction dispute analysis, account for 36.9% of project conflicts. Proposals without clear dispute resolution terms, mediation provisions, or arbitration clauses leave both parties vulnerable to costly litigation. Any proposal failing to specify material temperatures, compaction standards, or warranty terms requires additional scrutiny before acceptance.

How Can Asphalt Coatings Company Streamline Your Asphalt Paving Proposal Experience?

Asphalt Coatings Company streamlines your asphalt paving proposal experience by integrating comprehensive documentation systems with transparent pricing and clear communication protocols. Professional contractors eliminate guesswork through detailed scope definitions, precise material specifications, and documented timelines that prevent the 36.9% of disputes caused by scope changes globally. The streamlined process includes digital proposal delivery, itemized cost breakdowns, and visual documentation that ensures all parties understand project requirements before work begins.

Can Asphalt Coatings Company Create a Customized Proposal for Your Project?

Yes. Asphalt Coatings Company creates customized proposals by analyzing site conditions, traffic patterns, and performance requirements to design solutions tailored to your project. The customization process evaluates factors such as required thickness (2-3 inches for residential, 6-8 inches for loading docks), drainage patterns, and ADA compliance needs for commercial properties. According to a 2024 industry analysis, projects with customized proposals experience 40% fewer change orders compared to generic estimates. Each proposal incorporates site-specific considerations including local permit requirements, weather windows, and material selections from standard hot-mix at $100-$150 per ton to polymer-modified options at $150-$220 per ton.

What Are the Key Takeaways About What a Professional Asphalt Paving Proposal Should Include We Covered?

The key takeaways about what a professional asphalt paving proposal should include are eight essential components: detailed project scope, material specifications, cost breakdowns, payment terms, warranties, legal compliance, supporting documentation, and evaluation criteria. Critical elements encompass site layouts with ADA-compliant 2% maximum slopes, asphalt mixture specifications at 95% aggregate and 5% binder, itemized pricing averaging $7-$13 per square foot installed, and warranty periods ranging 1-5 years for private projects. Professional proposals document insurance requirements including $1-2M general liability coverage, specify compaction density standards of 92-96%, and outline maintenance schedules requiring sealcoating every 2-3 years. These comprehensive proposals prevent the 21.5% of disputes caused by design errors and ensure projects join the 400 million tons of quality asphalt installed annually across America’s 2.7 million miles of paved roads.