Signing an asphalt paving contract without asking the right questions is like driving on a damaged road—you’re headed for problems. If you’re planning an asphalt paving project and feeling uncertain about what to ask contractors before committing, we understand your concern. We’re here to guide you through the essential questions that protect your investment and ensure a successful paving project.

Asphalt paving contracts are legally binding agreements between property owners and paving contractors that define the scope, materials, timeline, and costs for installing or repairing asphalt surfaces. According to the Associated General Contractors of America, 2025: Poorly drafted or incomplete contract documents are the top cause of construction disputes, with the average dispute in North America reaching $60.1 million in value and taking 13.1 months to resolve. The National Asphalt Pavement Association’s Diamond Commendation Program verifies that contractors following best practices demonstrate enhanced worker safety, quality product production, and improved community reputation through third-party verification.

“Good workers don’t quit companies, they quit managers,” notes the 2017 Fintech Report on paving business failures, emphasizing that clear communication before signing predicts issue handling quality during construction.

Key takeaways from this comprehensive guide include:

- Understanding why thorough contractor vetting protects your investment through proper licensing, insurance, and industry certifications

- Learning what qualifications and experience to verify, including NAPA Diamond Commendations and past project references

- Identifying specific contract details like scope of work, material specifications, and payment terms that prevent disputes

- Discovering how to ensure projects meet expectations through clear timelines, warranties, and change order procedures

- Knowing permit responsibilities, site preparation requirements, and local regulations that affect your project

- Planning for aftercare and maintenance with proper instructions and ongoing support from contractors

- Recognizing how asking the right questions helps choose the best contractor and evaluate contracts effectively

This article provides a comprehensive framework for evaluating asphalt paving contracts, covering everything from initial contractor qualifications through long-term maintenance planning, following the proven strategies that industry leaders use to ensure successful projects while avoiding the pitfalls that cause 63.5% of construction companies to fail within their first five years.

Here’s an immediately actionable tip: Never pay the full amount upfront—industry best practices recommend a payment schedule of 10-50% deposit, with progress payments tied to specific milestones like site preparation and base installation completion.

By thoroughly understanding these critical questions and contract components, you’ll be equipped to make informed decisions that protect your investment and ensure your asphalt paving project delivers lasting value and performance.

Why Is It Important to Ask Questions Before Signing an Asphalt Paving Contract?

Asking questions before signing an asphalt paving contract protects your investment from failed contractors, expensive disputes, and substandard work. A 2017 Fintech Report reveals construction has the lowest success rate for small businesses of all industries, with 63.5% of construction companies failing within their first 5 years. Construction disputes in North America averaged $60.1 million in value and took 13.1 months to resolve in 2025. The Arcadis 2025 report identifies poorly drafted or incomplete contract documents as the top cause of construction disputes. Proper questioning reveals contractor qualifications and contract terms that determine project success.

What Risks Might You Face by Not Asking the Right Questions?

The risks of not asking the right questions include hiring unlicensed contractors, facing unresolved disputes, and receiving incomplete work. Unlicensed contractors face penalties ranging from $1,000 to $50,000 depending on state, with some states denying lien rights to unlicensed contractors. There are three main risk categories when signing contracts without proper vetting:

- Financial risks: Construction disputes averaging $60.1 million and taking 13.1 months to resolve

- Legal risks: Working with unlicensed contractors who lack lien rights and face penalties

- Completion risks: 63.5% contractor failure rate within 5 years threatens project completion

The Arcadis 2025 report confirms poorly drafted contract documents cause most construction disputes. These risks compound when property owners sign contracts without understanding scope, warranties, or payment terms.

How Can Thoroughly Vetting Your Contractor Protect Your Investment?

Thoroughly vetting your contractor protects your investment through verified credentials, financial safeguards, and quality assurances. NAPA Diamond Commendation contractors demonstrate enhanced worker safety, quality product production, and improved community reputation through third-party verification. Federal and state-financed construction projects over $150,000 require performance bonds guaranteeing 100% of contract price. Insurance requirements typically include a $1-2 million liability minimum, protecting property owners from financial exposure.

| Protection Type | Requirement | Value |

| Insurance Coverage | Liability Minimum | $1-2 million |

| Performance Bonds | Coverage Amount | 100% of contract |

| Licensed Status | Knowledge Testing | Trade & business law exams |

| Contract Clarity | AGC Standards | Reduced claims risk |

Contractors with proper licensing prove trade knowledge and business law understanding through required examinations. AGC standards confirm detailed contracts with clear scope reduce claims and facilitate contract administration. Verification processes ensure contractors meet industry standards before starting your project.

What Qualifications and Experience Should an Asphalt Paving Contractor Have?

The qualifications and experience an asphalt paving contractor should have include proper licensing, adequate insurance coverage, and recognized industry certifications that ensure legal compliance and quality workmanship. Verifying these qualifications protects property owners from financial liability and ensures project completion to professional standards. The following qualifications distinguish reputable contractors from unqualified operators.

How Do You Verify a Contractor’s Licensing and Insurance?

Contractor licensing and insurance verification requires checking state databases and requesting current certificates directly from providers. Most states require general contractor licenses for prime contracts, with thresholds varying by state from $500 to $50,000. License verification includes confirming trade knowledge exam completion, business law exam passage, and background check clearance.

Insurance requirements protect property owners from liability exposure during construction. Contractors must provide certificates showing general liability coverage averaging $77 per month, workers’ compensation at $260 monthly, and commercial auto insurance at $173 per month. Commercial contracts typically require $1-2 million liability limits. Workers’ compensation insurance becomes mandatory in most states when contractors employ workers.

State licensing boards maintain online databases for verification. Property owners should request certificates of insurance directly from insurance carriers, not contractors, to confirm active coverage.

What Past Projects or References Can the Contractor Provide?

The past projects or references a contractor should provide include recently completed jobs similar in size and scope, along with verifiable client contacts who can confirm performance and results. References should include projects completed within the last 2-3 years to assess pavement durability over time. Portfolios must show experience with comparable project types, such as residential driveways, commercial parking lots, or municipal roads, matching your traffic loads.

According to ConsensusDocs contracts endorsed by 40+ construction organizations, reference verification represents industry best practice. Contact references directly to ask about project completion, budget adherence, and problem resolution. A Bain & Company study found customer service issues cause client defection 4 times more often than price or product concerns.

Contractors should provide 3-5 references with contact information, project descriptions, and completion dates. Site visits to completed projects reveal workmanship quality firsthand.

What Industry Certifications or Training Do Reputable Contractors Hold?

The industry certifications or training reputable contractors hold include nationally recognized programs that verify technical expertise, regulatory compliance, and commitment to quality standards. The National Asphalt Pavement Association (NAPA) represents 1,100 member companies and awards Diamond Commendations in five categories: plant operations, quality control, paving excellence, environmental practices, and safety performance. Diamond Achievement certifications assess regulatory compliance through third-party verification.

State projects require specialized certifications meeting or exceeding state requirements. AASHTO and ASTM certifications indicate compliance with material specifications and test methods. These certifications result in enhanced worker safety, increased operational efficiencies, and improved employee morale according to NAPA data.

Reputable contractors display certifications prominently and maintain current training records. Certification verification ensures contractors understand proper installation techniques, material handling, and safety protocols essential for successful asphalt paving projects.

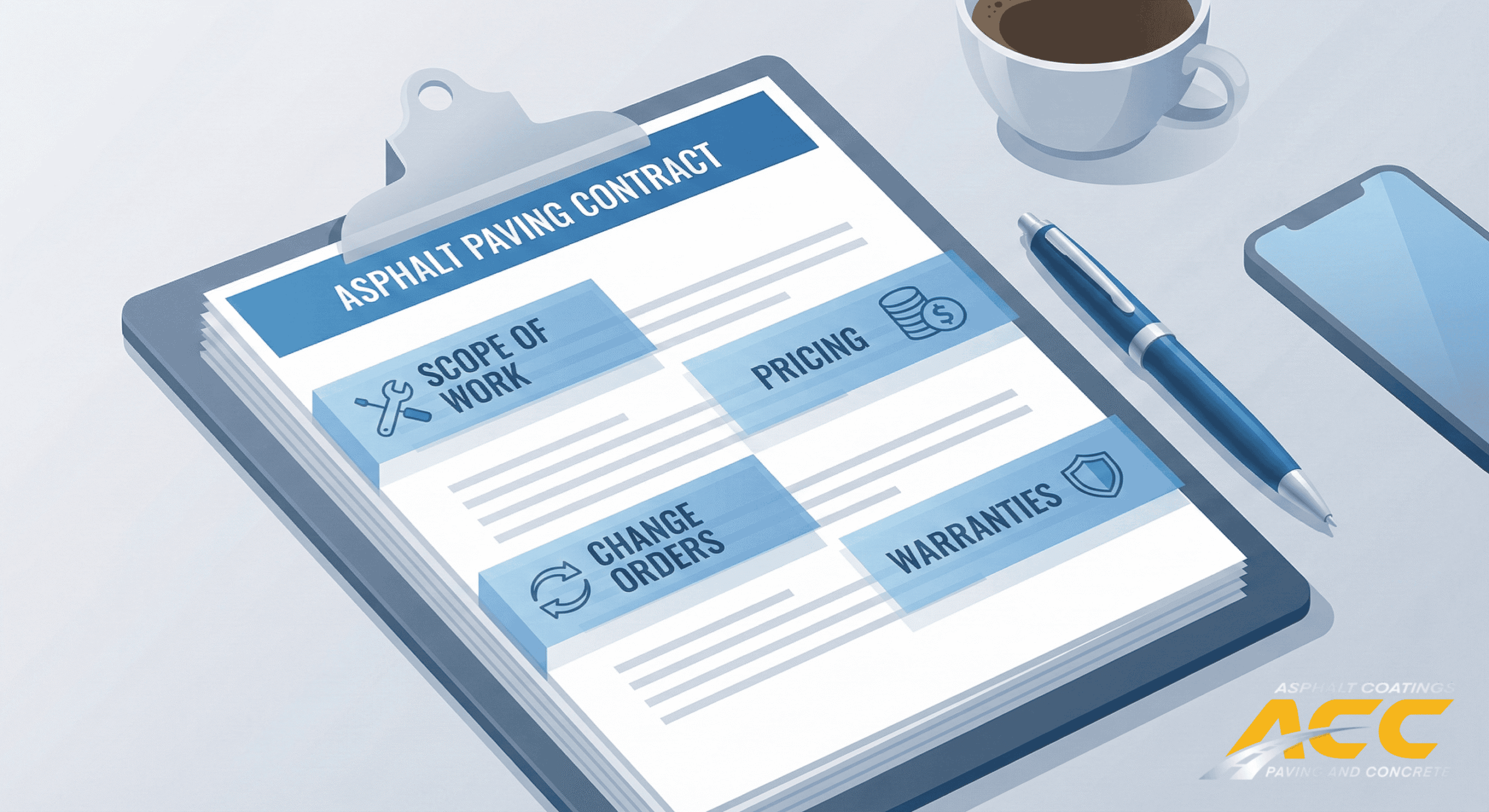

What Specific Details Should the Asphalt Paving Contract Include?

The specific details an asphalt paving contract should include are clearly defined expectations, responsibilities, remedies, and protections that prevent disputes and misunderstandings. The contract serves as your primary defense against disputes, which averaged $60.1 million in value and took 13.1 months to resolve in North America according to the 2025 Arcadis report. The following sections outline essential contract components, material specifications, and payment structures.

What Are the Key Components of a Comprehensive Paving Contract?

The key components of a comprehensive paving contract are scope of work, pricing structure, change order procedures, dispute resolution terms, and modification requirements. Scope of work must specify site prep, base installation, asphalt application, striping, drainage, and grading to prevent surprise charges. Fixed price agreements offer better protection than itemized breakdowns by eliminating unexpected cost increases.

Change order procedures require clear documentation including:

- Request submission steps

- Cost calculation methods

- Timeline impact assessments

- Required approval signatures

Dispute resolution terms should specify mediation or arbitration procedures. Construction law attorneys recommend arbitration clauses to avoid expensive litigation costs. Contract modifications must follow documented change order requirements with written approvals from both parties before work proceeds.

How Are Scope of Work and Material Specifications Outlined in the Contract?

Scope of work and material specifications are outlined through detailed descriptions of asphalt mix types, thickness requirements, compaction standards, and application temperatures. Material specifications must include asphalt mix grade, hot versus cold mix designation, aggregate size and composition, and recycled content percentage.

| Asphalt Application Area | Specification Type | Required Standard | Industry Source |

| Light traffic areas | Thickness requirement | 2-3 inches | Industry standard |

| Heavy traffic zones | Thickness requirement | 4-6 inches | Industry standard |

| Minimum lift | Thickness standard | 3x nominal aggregate size | Asphalt Institute |

| Compaction | Density requirement | 92-96% | Industry standard |

| Layer thickness | Range per application | 2-8 inches | Project specifications |

Application temperature specifications determine pavement durability and lifespan. The Asphalt Institute standards require minimum lift thickness at least three times the nominal maximum aggregate size for proper compaction and performance.

What Payment Terms and Schedules Should Be Clearly Defined?

The payment terms and schedules that should be clearly defined include milestone-based payments, escalation clauses, and completion requirements that align compensation with project progress. Industry best practices recommend never paying the full amount upfront.

Typical payment schedules include:

- Initial deposit: 10-50% upon contract signing

- Site preparation completion: 25-35% payment

- Base installation finish: 25-35% payment

- Final payment: Remainder upon project completion

Escalation clauses protect against material price fluctuations. Contracts should include a 10% trigger threshold with 15-20% cap for price changes. Federal projects may allow ±50% price variations with proper documentation. Payment terms must match construction milestones with exact amounts and due dates specified to prevent payment disputes.

Understanding these contract details ensures your asphalt paving project proceeds smoothly with clear expectations and protected interests for all parties involved.

How Do You Ensure the Asphalt Paving Project Meets Your Expectations?

Ensuring your asphalt paving project meets expectations requires asking specific questions about timelines, warranties, and change order procedures before signing the contract. A 2025 Arcadis report reveals construction disputes average 13.1 months to resolve, making clear contract terms essential for project success. Understanding project schedules, guarantee coverage, and modification protocols protects your investment from common contractor disputes.

What Questions Help Clarify Project Timeline and Potential Delays?

The questions that help clarify project timeline and potential delays address start dates, completion deadlines, phase milestones, and how interruptions such as weather are handled. The contract must specify exact start dates, end dates, phase milestones, weather delay provisions, and deadline consequences. Spring and early fall provide optimal paving conditions with temperatures between 50-85°F, while winter paving should be avoided in freeze-thaw climates.

New asphalt requires minimum curing times before use. The surface needs 24 hours before foot traffic and 72 hours before vehicle use. Weather delays, equipment availability, and drying requirements all impact schedules.

Key timeline questions include:

- What are the exact start and completion dates?

- How are weather delays handled and documented?

- What milestones trigger progress payments?

- What penalties apply for missed deadlines?

- How much notice is required for schedule changes?

Understanding these timeline factors prevents disputes and ensures realistic expectations for project completion.

How Are Project Guarantees and Warranties Addressed in the Contract?

Project guarantees and warranties are addressed through specific coverage terms defining duration, scope, and claim procedures. According to FHWA standards, materials and workmanship warranties typically cover 2-4 years. Short-term performance warranties range 5-10 years for public projects, while long-term warranties extend 10-20 years with contractors responsible for pavement performance.

Residential paving includes 1-year workmanship warranties. Commercial projects offer 1-3+ year coverage. The warranty must specify:

- Installation defects covered

- Material failure provisions

- Structural issue remedies

- Coverage exclusions

- Claim submission process

Clear warranty terms protect against premature failures and ensure contractor accountability for quality workmanship throughout the coverage period.

What Provisions Should Be Included for Change Orders or Unexpected Issues?

The provisions that should be included for change orders or unexpected issues are cost calculation methods, timeline impact assessments, and formal approval requirements from both parties. A 2025 construction dispute analysis ranked change orders as the second most common cause of project conflicts. The contract must specify how adjustments are calculated and documented.

Required change order elements:

- Written approval procedures before work begins

- Cost adjustment calculation methods

- Timeline modification protocols

- Documentation requirements for all changes

- Notice periods for proposed modifications

Construction law attorneys identify missing change order procedures as a major contract red flag. Clear modification protocols prevent unauthorized work and surprise charges while protecting both parties when unexpected issues arise during paving installation.

What Should You Know About Permits, Regulations, and Site Preparation?

What you should know about permits, regulations, and site preparation includes legal requirements, compliance responsibilities, and physical conditions that affect project approval and performance. According to a 2025 Arcadis report, poorly drafted or incomplete contract documents are the top cause of construction disputes. Understanding permit responsibilities, conducting thorough site assessments, and complying with regulations prevents costly delays and legal issues.

How Do You Determine Who Is Responsible for Obtaining Permits?

You determine who is responsible for obtaining permits by explicitly defining permit duties and associated costs within the paving contract. Many areas require permits for driveway extensions or paving to ensure safety, zoning, and drainage compliance. Driveway permits become necessary when accessing public roads. Construction work within State Highway Right-of-Way requires special permits. The EPA Construction General Permit applies to projects disturbing certain acreage.

Your contract should specify which party obtains permits and handles associated costs. Some contractors include permit acquisition in their services, while others require property owners to manage this process. Clarifying this responsibility prevents project delays and unexpected expenses.

What Pre-Construction Site Assessments Should Be Conducted?

The pre-construction site assessments that should be conducted include evaluations of soil stability, drainage conditions, grading requirements, and existing site constraints. Base layer preparation requires proper grading, compaction, and often crushed stone installation. Poor drainage causes cracks, potholes, and structural issues requiring evaluation of slope and water management systems.

Site assessments should identify:

- Buried utility lines requiring protection or relocation

- Unstable soil conditions needing stabilization

- Access limitations for equipment and materials

- Existing drainage patterns and improvement needs

Compaction testing ensures 92-96% density requirements are achievable. Drainage solutions may include channels, catch basins, or special grading requirements. These assessments determine project feasibility and additional preparation costs before contract finalization.

Which Local or Environmental Regulations Could Affect Asphalt Paving Projects?

The local or environmental regulations that could affect asphalt paving projects include accessibility requirements, stormwater management rules, emissions controls, and waste handling guidelines. EPA Paving and Roofing Materials Effluent Guidelines (40 CFR Part 443) govern waste management throughout construction. VOC emissions control requirements apply to cutback asphalt usage, limiting material options in certain regions.

| Regulation Type | Requirement | Impact on Project |

| ADA Compliance | Mandatory for commercial projects | Slope and accessibility specifications |

| Stormwater Management | Required for disturbing certain acreage | Additional planning and permits needed |

| NAPA Initiative | Net zero carbon by 2050 | Material selection changes |

| EPA Guidelines | 40 CFR Part 443 compliance | Waste handling procedures |

Commercial projects require ADA compliance for accessibility. Stormwater management plans become mandatory for construction activities disturbing specified acreage. According to NAPA’s “The Road Forward” initiative targeting net zero carbon emissions by 2050, material choices increasingly consider environmental impact. Understanding these regulations ensures compliance and prevents costly violations during your paving project.

What Aftercare, Maintenance, and Follow-Up Should You Discuss?

The aftercare, maintenance, and follow-up topics you should discuss include care schedules, warranty processes, inspection procedures, and long-term support options. Maintenance requirements vary between residential driveways and commercial parking lots, with each requiring specific care schedules and procedures. Understanding warranty processes, follow-up protocols, and ongoing support options ensures your pavement maintains its integrity for decades.

What Maintenance Instructions Should Be Provided After Paving?

Maintenance instructions for new asphalt paving include sealcoating schedules, crack repair timelines, and surface care guidelines. Residential driveways require sealcoating every 2-3 years, while commercial parking lots need treatment every 1-3 years. The first sealcoat should occur after one summer cycle to allow proper asphalt curing.

Annual crack repairs prevent water infiltration and extend pavement life significantly. Asphalt driveways last up to 20 years with proper maintenance routines. During the first two years, keep surfaces clean while observing for potential issues requiring attention.

How Does the Contractor Handle Follow-Up or Post-Installation Issues?

The contractor handles follow-up or post-installation issues by following defined warranty claim processes, response timelines, and inspection procedures outlined in the contract. Documentation for warranty claims must include clear submission procedures with specific requirements. Contractors should provide a single point of contact for all post-installation concerns.

Response time specifications for warranty issues belong in the contract terms. Final inspection and punch list procedures ensure satisfaction before releasing final payment. Each warranty claim requires proper documentation as outlined in contract provisions.

What Ongoing Support or Service Can You Expect After the Project?

The ongoing support or service you can expect after the project includes maintenance contracts, warranty coverage, and pavement preservation strategies. Life-cycle costs for Hot Mix Asphalt remain significantly lower than concrete when proper maintenance occurs. According to preservation strategies, right treatments at the right time extend road life by decades.

Contractors often offer maintenance contracts covering sealcoating and crack filling services. Routine reactive-type annual maintenance costs remain small compared to initial construction investment. Standard warranties include 3-year limited coverage for full depth replacement and 1-year for overlays.

Understanding aftercare, maintenance requirements, and follow-up procedures protects your asphalt investment while maximizing pavement lifespan through proper care and timely interventions.

How Can Asking the Right Questions Help You Choose the Best Asphalt Paving Contractor?

Asking the right questions helps you choose the best asphalt paving contractor by revealing their expertise, transparency, and commitment to quality. Professional contractors welcome detailed inquiries about licensing, materials, and warranties. The following sections explain how Asphalt Coatings Company addresses contract questions and what to remember when evaluating paving agreements.

How Can Asphalt Coatings Company Answer Your Questions About Asphalt Paving Contracts?

Asphalt Coatings Company answers your questions about asphalt paving contracts by providing clear explanations, documented expertise, and transparent guidance throughout the review process. Professional contractors explain complex terms in simple language without technical jargon. Legitimate contractors provide adequate review time without pressure tactics.

Experienced contractors recommend specific materials based on three factors: property needs, traffic load, and budget constraints. There are multiple asphalt mix types, such as hot mix, warm mix, and cold patch formulations. Qualified contractors offer realistic project timeframes with transparent delay explanations.

Reputable contractors maintain commercial-grade equipment for superior results. Equipment quality directly impacts pavement smoothness and longevity. Well-maintained pavers, rollers, and spreaders ensure consistent asphalt application.

Customer education remains central to professional contracting services. Contractors should explain warranty coverage, maintenance requirements, and payment schedules clearly. This transparency builds trust and prevents disputes during construction.

What Are the Most Important Points to Remember When Evaluating an Asphalt Paving Contract?

The most important points to remember when evaluating an asphalt paving contract include industry benchmarks, sustainability factors, and legal protections that safeguard your investment. The United States has 138,000 paving contractors generating $18.9 billion in industry revenue as of 2025. Top 50 paving contractors generated $1.906 billion in sales with 40% achieving profit margins exceeding 20%.

Asphalt maintains a 99% recycling rate as America’s most recycled product. Contractors use an average of 22.2% reclaimed asphalt pavement (RAP) in new mixtures. This recycling reduces material costs while maintaining quality standards.

Construction law attorneys recommend professional contract review before signing. Legal review ensures proper liability allocation and dispute resolution procedures. Clear pre-construction communication predicts issue handling quality during project execution according to legal experts.

Contract evaluation requires checking specific elements:

- Scope definitions with exact square footage

- Material specifications including thickness and grade

- Payment schedules tied to completion milestones

- Warranty terms covering workmanship and materials

- Change order procedures with cost calculations

Professional contractors provide detailed contracts addressing all construction phases. Complete documentation protects both parties and ensures project success through clear expectations and accountability measures.