Deciding between the lowest bid and best value when choosing an asphalt contractor means weighing short-term price savings against long-term project performance, budget control, and pavement durability. We understand that property owners face this dilemma with every paving project, wondering whether saving money upfront might cost more in the long run. We’re here to help you navigate this complex decision with data-driven insights and proven industry expertise.

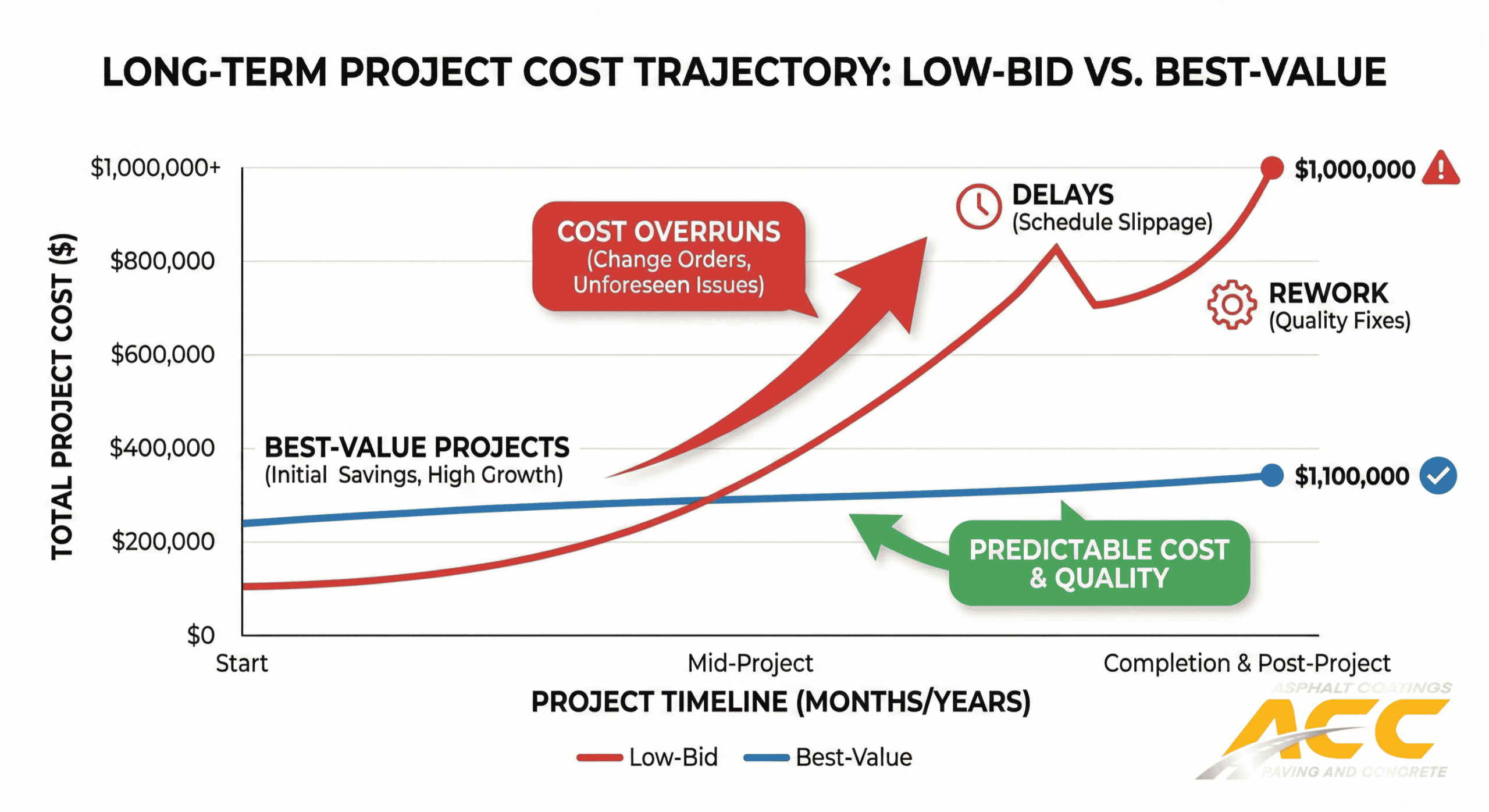

According to the Federal Highway Administration (FHWA), 2002: 87% of highway program value is delivered using design-bid-build contracting, which is overwhelmingly low-bid based, yet 57% of these low-bid projects exceed their original budgets. “Selecting based on a low bid practically guarantees you will end up with the least qualified contractor for your project,” warns Dr. Thomas C. Schleifer in Engineering News-Record.

In 2024, a comprehensive industry study by Messerly Concrete on Utah construction projects found that best-value contractors cost only about 1% more upfront on average but see 37% less cost growth during construction compared to low-bid projects.

Key Points & Takeaways:

- Low-bid vs best-value selection fundamentally differs in evaluation criteria beyond price

- Choosing lowest bid impacts quality through increased defects and rework requirements

- Best value encompasses contractor experience, materials quality, and lifecycle performance

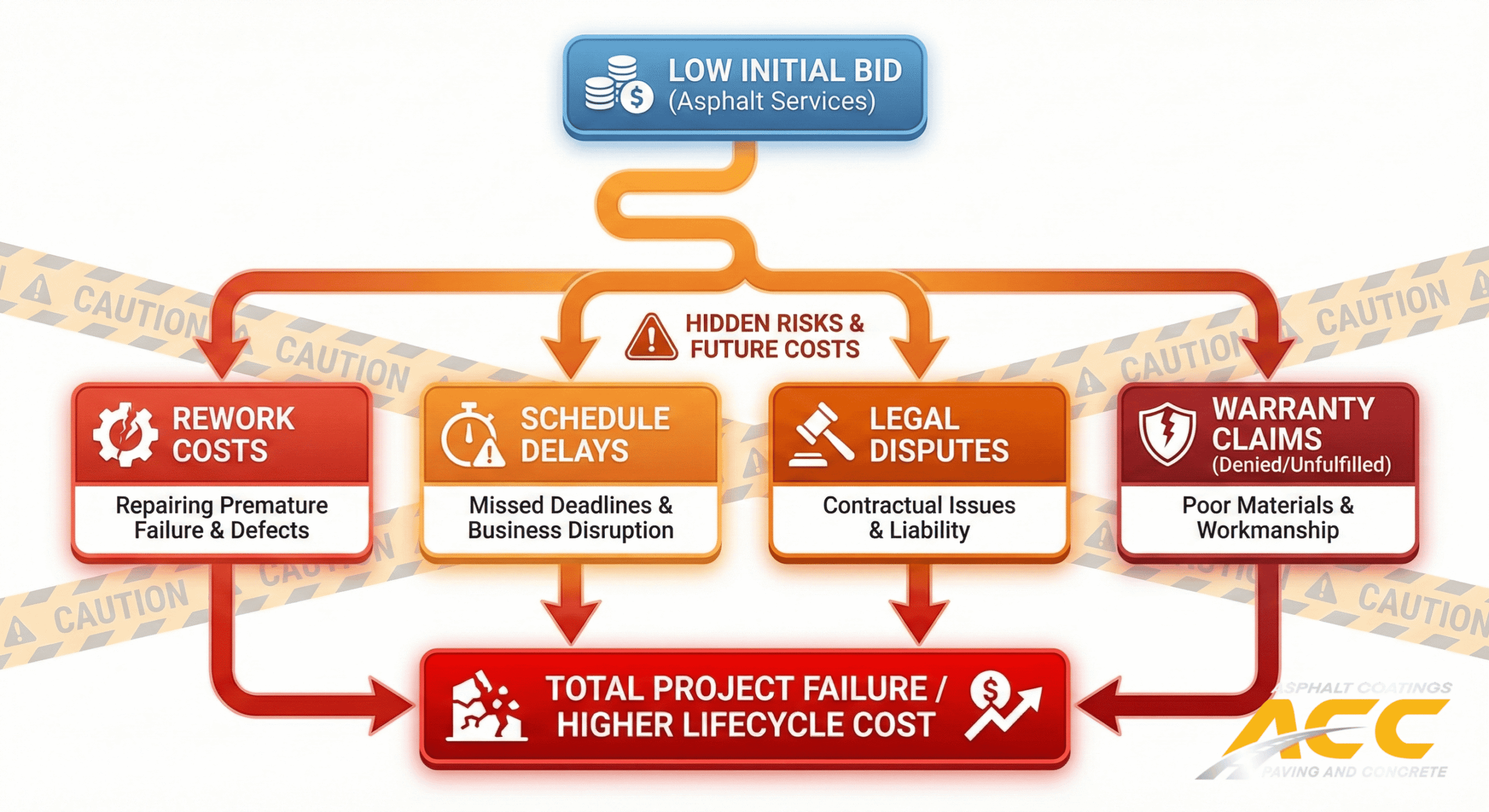

- Hidden costs of low-bid selection include project delays and extensive repairs

- Contractor experience, licensing, and reputation serve as critical selection factors

- Material specifications and installation techniques directly affect pavement longevity

- Comprehensive warranties and maintenance services protect your investment

- Detailed written proposals reveal contractor competence and project understanding

High-Level Summary:

We begin by exploring the fundamental differences between lowest-bid and best-value procurement, revealing how each approach impacts project outcomes. We then examine quality implications, uncovering why low-bid projects often require costly repairs. Our analysis of best-value criteria demonstrates how evaluating experience and capabilities prevents failures. We investigate hidden costs including rework expenses and schedule delays that transform apparent savings into budget overruns. Our review of contractor qualifications emphasizes the importance of licensing, experience verification, and reference checking. We detail how material specifications and modern paving techniques signal quality workmanship. Finally, we outline warranty protections and proposal evaluation methods that help identify the truly best-value contractor for your project.

Practical Tips:

- Request detailed breakdowns of materials specifications and installation methods in all proposals to compare quality approaches, not just prices

- Verify contractor licenses and insurance before accepting any bid, as unlicensed contractors may void your legal protections and result in inferior work

Summary:

Our comprehensive analysis demonstrates that while lowest-bid selection may appear cost-effective initially, best-value procurement consistently delivers superior long-term results with minimal upfront premium. The data clearly shows that evaluating contractors based on experience, quality commitments, and proven performance prevents the budget overruns and quality failures that plague low-bid projects. As we move forward to examine specific evaluation criteria, remember that your asphalt investment deserves a contractor selection process that prioritizes lasting value over temporary savings.

What Are the Main Differences Between Choosing the Lowest Bid and Best Value in Asphalt Projects?

The main differences between choosing the lowest bid and best value in asphalt projects are procurement focus, cost outcomes, and quality assurance standards. According to a 2002 FHWA report, 56% of design-build asphalt projects use low bid procurement while 38% use best value procurement methods. Low bid selection prioritizes price alone. Best value procurement evaluates experience, performance, and delivery capability alongside cost. Best-value contractors cost only 1% more upfront but see 37% less cost growth during construction compared to low-bid projects. A 2021 ASCE study reveals that 82% of best-value design-build projects still award to the lowest bid, suggesting best-value procurement often fails to account for non-price factors. Understanding these differences helps property owners select contractors who deliver lasting asphalt surfaces rather than costly repairs.

How Can Choosing the Lowest Bid Impact the Quality of Asphalt Work?

Choosing the lowest bid impacts the quality of asphalt work through budget overruns, missed deadlines, and structural failures. According to 2024 Messerly Concrete data, 57% of low-bid projects exceed original budgets. The same study shows 46% of low-bid projects miss critical deadlines. Dr. Thomas C. Schleifer states in ENR that selecting based on low bid practically guarantees ending up with the least qualified contractor. Low-bid contractors cause specific quality issues such as cracked concrete, uneven floors, and structural problems requiring expensive rework. These quality impacts transform initially attractive low prices into significantly higher total project costs through repairs and replacements.

What Does “Best Value” Mean When Evaluating Asphalt Contractors?

Best value when evaluating asphalt contractors means assessing multiple performance factors beyond price to ensure project success. Messerly Concrete defines best value procurement as evaluating contractors on experience, past performance, and delivery ability—not just price. FHWA defines quality assurance as all planned and systematic actions providing confidence that facilities perform satisfactorily in service. ASC identifies best value components including financial stability, past performance, experience, and key personnel availability. EOXS highlights quality of workmanship, specification adherence, and communication effectiveness as key best-value metrics. This comprehensive evaluation approach identifies contractors who deliver durable asphalt surfaces meeting long-term performance requirements.

What Are the Hidden Costs or Risks of Choosing the Lowest Bid for Asphalt Services?

The hidden costs of choosing the lowest bid for asphalt services are rework expenses, cost overruns, and extensive repair requirements. McKinsey reports rework from poor planning and execution consumes 20-30% of total project costs, turning $10 million jobs into $13 million problems. Nassar et al. analyzed 219 projects finding 4% average cost overrun above bid price for asphalt paving. In 2018, Tran et al. documented design-build projects had 7.4% average cost growth versus 3.6% for design-bid-build. ConstructConnect reports highway construction costs increased 68% since 2021, with below-average bidder competition contributing to increases. A 2018 ENR case study documents a $2.5 million firehouse project requiring $1.5 million in repairs—60% of the original contract—due to low-bid contractor failures. These hidden costs demonstrate how lowest bid selection often results in higher total project expenses than best value approaches.

Why Is Contractor Experience and Reputation Important in the Selection Process?

Contractor experience and reputation are important in the selection process because inexperienced or unstable contractors significantly increase the risk of project failure, delays, and financial loss. A 2024 ENR report shows sophisticated buyers avoid design-bid-build processes precisely because inexperienced contractors create project failures. The NCDOT contractor prequalification process ensures vendors have sufficient ability and experience to perform work. Twenty-four states require commercial paving contractor licenses, with average requirements of $361 in fees, 417 days of education, and one exam. The following sections detail how to assess experience, evaluate references, and verify licensing.

What Questions Should You Ask to Assess an Asphalt Contractor’s Experience?

The questions to assess an asphalt contractor’s experience are: current workload capacity, typical project scope, specific project-type experience, and technical certifications. Giroux Glass recommends asking about current and backlog work to assess capacity. Partner ESI suggests requesting information about typical work completed and largest projects undertaken. SBN Software emphasizes inquiring about specific experience with your project type, not just years in business.

Technical qualifications matter equally. NICET Construction Materials Testing Asphalt certification verifies laboratory and field technician competence. The Asphalt Institute’s Paving Inspector Certification (PIC) demonstrates quality control and assurance capabilities in key personnel.

How Do Reviews and References Reflect the Value an Asphalt Contractor Offers?

Reviews and references reflect value through verified past performance and safety records. Architectural Digest identifies bad or zero reviews as major red flags when selecting contractors. Reddit users recommend asking to see previous work and meeting previous clients when possible. Leritz Busy Bee states reputable asphalt paving companies provide references and portfolios before bidding begins.

Safety records reveal operational excellence. ConstructConnect includes safety record checks in contractor vetting processes. Travelers Insurance advises getting multiple estimates and talking to several contractors for written quotes to compare value propositions across vendors.

How Does Licensing and Insurance Factor Into Your Decision?

Licensing and insurance factor into decisions by ensuring legal compliance and financial protection. Procore reports licensing ensures contractors have expertise levels to handle potentially dangerous situations through state-administered trade knowledge tests. Some states won’t grant lien rights to unlicensed contractors according to Procore’s construction law analysis.

NFP confirms construction bonds are statutory requirements in many states before beginning paving projects. Honey Domen identifies lack of proper licensing as a critical evaluation red flag. These credentials protect both contractor payment rights and client project investments through verified competency and financial backing.

Which Materials and Techniques Should Influence Your Evaluation of Asphalt Contractors?

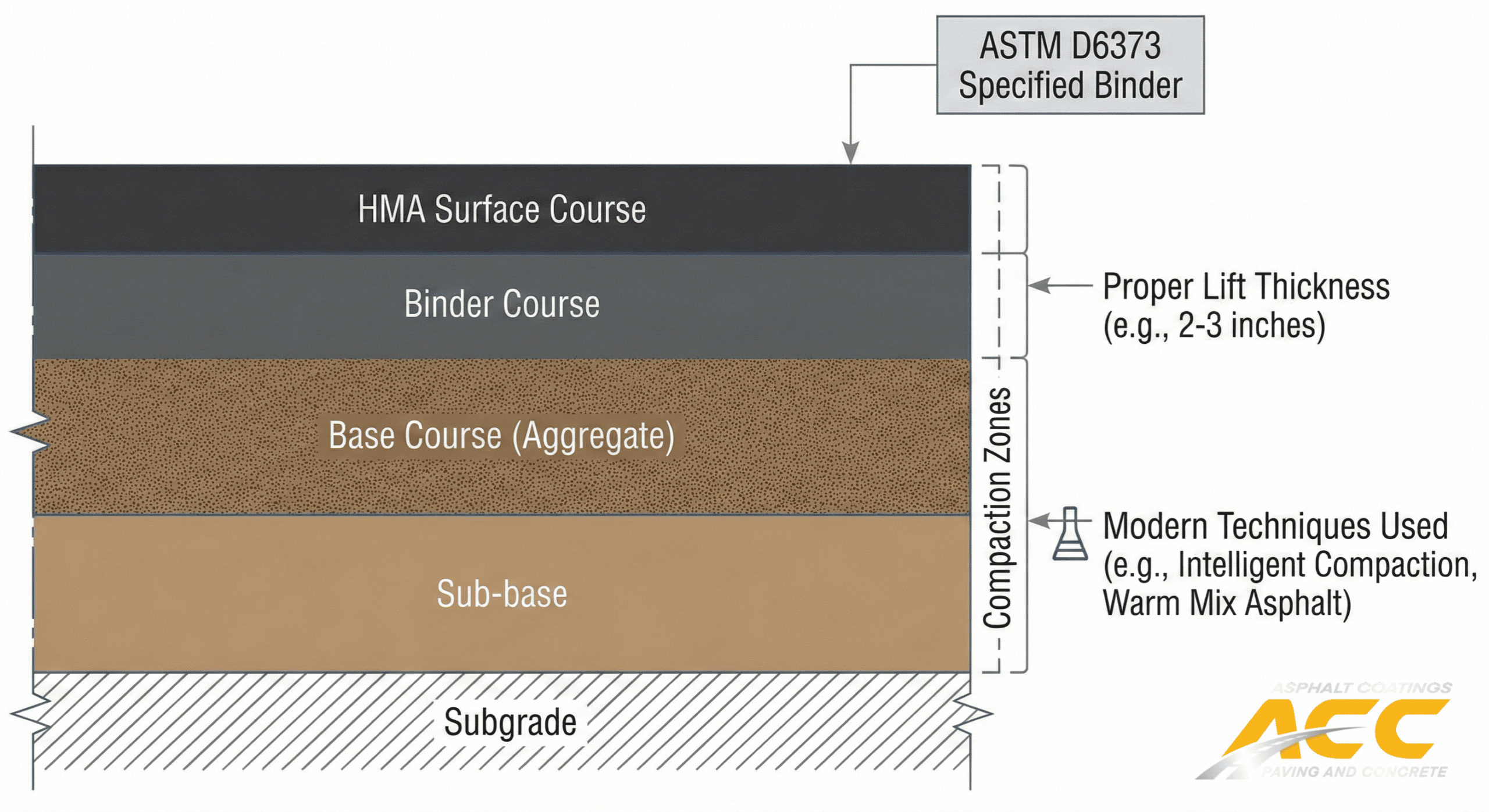

Material specifications and paving techniques directly determine your asphalt project’s longevity and performance. ASTM road and paving standards provide specifications ensuring strength and durability for safe application. Hot Mix Asphalt (HMA) requires production at 300-350°F with minimum lift thickness at least three times the nominal maximum aggregate size. Asphalt ranks as America’s most recycled material, delivering environmental benefits through sustainable construction practices. Well-maintained asphalt pavements last decades when contractors use quality materials meeting industry standards. Understanding material requirements and modern techniques helps distinguish contractors offering true best value from those cutting corners.

How Do Material Specifications Affect the Asphalt Project’s Long-Term Results?

Material specifications affect asphalt project long-term results through their direct impact on pavement durability and lifecycle costs. ASTM D6373 provides Performance-Graded Asphalt Binder specifications critical for pavement longevity. AASHTO M-320 Performance Graded asphalt binder specifications ensure quality, safety, and structural integrity. High-quality materials extend lifespan significantly while providing solid foundations that reduce erosion and structural damage risks. Asphalt pavements designed with longer service life reduce lifecycle costs, user delays, and environmental impacts compared to standard 20-year designs. Contractors following these specifications deliver pavements requiring less frequent rehabilitation and lower total ownership costs.

What Modern Techniques Signal a Best Value Approach in Asphalt Paving?

Modern techniques signaling best value in asphalt paving include perpetual pavement design, sustainable practices, and rigorous quality control. Perpetual Pavements never require complete removal and replacement, demonstrating advanced engineering approaches. Sustainable practices encompass recycling old pavement, using warm-mix asphalt, and adopting preventive maintenance to reduce waste and energy consumption. Quality control best practices involve improved data analysis, visual observations, and timely QC/QA report submission. Inspector responsibilities include verifying HMA placement and compaction meet specifications and industry standards. These techniques indicate contractors investing in long-term performance rather than minimum initial requirements.

How Transparent Should an Asphalt Contractor Be About Materials and Processes?

An asphalt contractor should be completely transparent about materials and processes throughout your project. Bid items must include specification section and code, material density, asphalt cement type and grade, and asphalt content percentages. Contractor quality control remains the contractor’s responsibility with agency acceptance through independent assurance protocols. Vague contracting details represent red flags indicating transparency lacks. Contract vagueness warns of potentially problematic contractors who may substitute inferior materials or skip critical processes. Transparent contractors provide detailed documentation, welcome questions, and explain their material choices and construction methods clearly before work begins.

What Role Do Warranties and After-Service Play in Choosing the Right Contractor?

Warranties and after-service commitments are critical factors that distinguish lowest-bid contractors from best-value providers in asphalt projects. According to FHWA research, short-term performance warranties typically range from 5-10 years depending on pavement type and project design, while industry practice shows asphalt paving warranties usually span 1-5 years per RSA Paving data. Long-term performance warranties have been documented by FHWA to reduce life cycle costs by improving pavement performance. Materials and workmanship warranties require contractors to correct defects caused by elements within their control. The following sections explore how warranties protect investments and what maintenance services matter most.

How Can Warranties Protect Your Asphalt Investment?

Warranties protect your asphalt investment through multiple bonding structures and coverage levels. FHWA research shows warranty bonds can use constant level, straight-line depreciation, stepped depreciation, or variable depreciation over the warranty length. Short-term warranty bonds typically include only replacing surface materials for full depth Hot Mix Asphalt (HMA), while long-term warranty bonding generally includes all paving materials according to FHWA standards. RSA Paving emphasizes that warranties should clearly outline exclusions and limitations. Bond costs depend on contractor factors including creditworthiness and project scope, as noted by Axcess Surety.

| Warranty Component | Coverage or Structure | Details / Scope | Source |

| Short-term bonds | Coverage scope | Surface materials only | FHWA |

| Long-term bonds | Coverage scope | All paving materials | FHWA |

| Warranty bonds | Depreciation methods | Constant, straight-line, stepped, variable | FHWA |

| Bond pricing | Key factors | Creditworthiness, project scope | Axcess Surety |

These warranty structures provide financial protection against premature pavement failure and workmanship defects.

What Should You Know About Maintenance and Repair Services After the Project?

Maintenance and repair services after project completion significantly impact total ownership costs over the pavement’s lifetime. Ontario Asphalt research indicates that over thirty or forty years of pavement service, maintenance and rehabilitation result in both direct costs for owners and indirect user costs. Asphalt Magazine analysis reveals maintenance costs in life-cycle cost analysis usually have minimal impact compared to initial and first rehabilitation costs. Pavetech data demonstrates that for the cost of a single mile of asphalt pavement, agencies can treat eight miles of existing roadways, adding approximately five years to their life. ACI Indiana confirms that preventive maintenance using quality materials can significantly extend pavement lifespan. Understanding these post-project service requirements helps evaluate the true value proposition of different contractors.

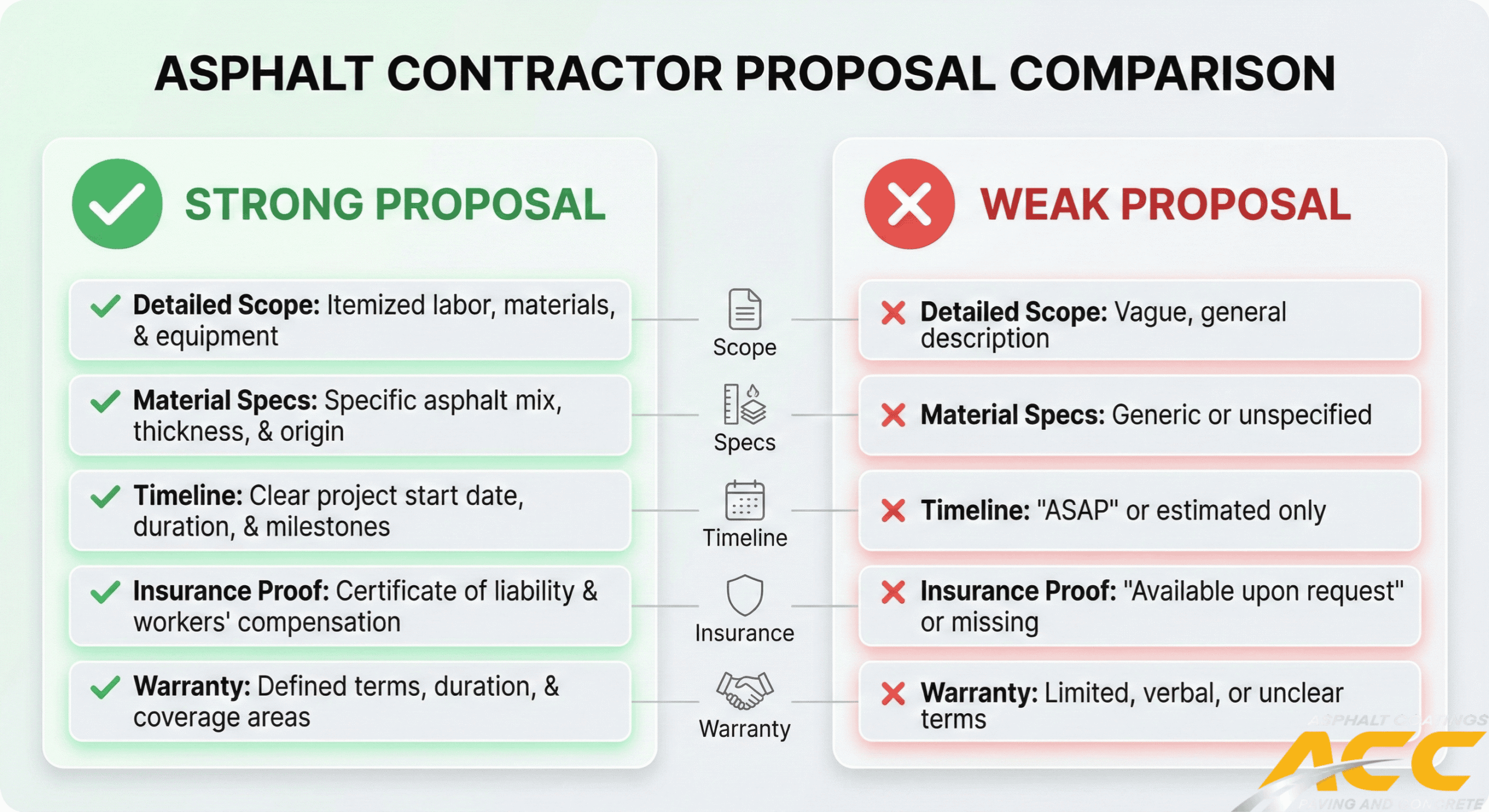

How Can a Detailed Written Proposal Help You Compare Asphalt Contractor Bids?

A detailed written proposal helps you compare asphalt contractor bids by establishing clear evaluation criteria that reflect merit areas necessary for your project requirements. According to a DOE report, evaluation criteria should reflect areas necessary to determine merit of a proposal, pertinent to stated requirements. The DAU emphasizes that proposal evaluation criteria must be clearly identified and defined in the request for proposal to conduct effective evaluation.

Bid variation presents significant challenges in contractor selection. A 2021 ASCE study found average bid dispersion of 27% in best-value design-build projects, indicating wide variation in contractor proposals. The same ASCE research shows engineering estimates average 2% more than awarded price, providing a benchmark for bid evaluation. These disparities underscore why detailed proposals matter for accurate comparison.

Written proposals reveal contractor capabilities through documentation quality. Comprehensive proposals demonstrate technical understanding, project approach, and resource allocation. Missing details or vague specifications signal potential problems. Professional contractors provide clear scope definitions, material specifications, and timeline commitments.

The following sections examine essential proposal components and warning signs that distinguish quality contractors from risky low bidders.

What Should Be Included in a Comprehensive Asphalt Project Proposal?

A comprehensive asphalt project proposal should include project overview, scope of work, timeline and schedule, cost estimates with payment terms, and contractor qualifications. ProjectMark identifies these five elements as fundamental proposal requirements. ProQSmart expands this to 10 essential RFP components: purpose, project overview, scope of work, project timeline, budget information, and evaluation criteria.

Site evaluation forms the proposal foundation. RM Service Co emphasizes three critical steps: site visit and project evaluation, scope of work with accurate measurements, and detailed bid proposal preparation. XAIT highlights technical understanding and competency, innovation demonstration through past experience, and past performance as key evaluation factors.

Financial transparency builds trust. Partner ESI recommends including financial statements, past company experience including typical work, and largest projects completed. These elements provide verifiable proof of contractor capability and stability.

| Asphalt Proposal Section | Required Proposal Details | Industry Standards & Best Practices |

| Proposal Components | Core Elements | 5-10 items |

| Site Evaluation | Measurement Accuracy | Required |

| Financial Documentation | Statements Included | Yes |

| Past Projects | Examples Provided | 3-5 typical |

Professional proposals balance detail with clarity, providing specific information without overwhelming technical jargon.

How Can You Detect Red Flags in a Contractor’s Bid or Proposal?

Red flags in a contractor’s bid or proposal include requests for large down payments, contract avoidance, poor communication, incomplete bids, and pricing errors. Multiple sources (Architectural Digest, HowStuffWorks, Honey Domen) identify excessive upfront payment demands without clear justification as a primary warning sign.

Contract reluctance signals problems. HowStuffWorks and Architectural Digest warn against contractors who won’t sign contracts or provide vague contract details. Lamont Bros and HowStuffWorks note inability to validate claims or poor communication skills as reliability indicators.

Incomplete bids create expensive problems. Messerly Concrete identifies incomplete bids that overlook important details as leading causes of scope gaps and change orders. Dr. Thomas C. Schleifer writes in ENR that “the bidder that makes the most mistakes gets the job is no longer amusing because it’s too close to the truth.”

Warning signs to watch for:

- Requests for 50% or more upfront payment

- Refusal to provide written contracts

- Missing insurance or license documentation

- Vague material specifications

- No timeline commitments

- Inability to provide recent references

These red flags often predict project delays, cost overruns, and quality issues that transform apparent savings into expensive mistakes.

How Should You Approach Lowest Bid vs Best Value Decisions With Professional Asphalt Services?

The approach to lowest bid versus best value decisions requires evaluating total project costs beyond initial price quotes. Professional asphalt services range from $6-9 per square foot nationally according to Asphalt Calculators data. Despite paving-only revenues declining from $913 million in 2023 to $698 million per Faith Paving reports, choosing contractors solely on price creates project risks. A 2024 ASCE study reveals current design-build best-value practices remain more conservative than other procurement methods. Messerly Concrete research emphasizes insisting on quality and competence prevents delays and budget overruns. The following subsections examine evaluation methods and key decision factors.

Can Asphalt Coatings Company Help You Evaluate Bids to Ensure Best Value?

Asphalt Coatings Company can help evaluate bids through systematic contractor assessment frameworks. The FHWA recommends performance-based contractor prequalification processes for selecting qualified contractors. According to IRMI guidelines, contractor qualification evaluates both business competency and builder qualifications simultaneously. TECH EHS specifies HSE Criteria Checklists must include:

- Experience in similar projects

- Technical expertise verification

- Current certifications status

- Regulatory compliance records

- Delivery capability metrics

ENR research demonstrates appropriate best-value contractor selection screens out contractors with poor performance histories before bidding begins. Professional evaluation services identify qualification gaps that lowest-bid selection overlooks.

What Are the Key Takeaways About Lowest Bid vs Best Value for Asphalt Contractors?

The key takeaways about lowest bid versus best value for asphalt contractors center on evaluating lifecycle costs rather than focusing solely on upfront savings. Messerly Concrete data shows slightly higher contract awards prevent massive overruns later. Their analysis asks: “What’s the use of saving 5% upfront if it means fighting through delays and paying 20% more in fixes later?” A documented case involved a $5 million municipal project doubling in cost due to contractor failures, proving the lowest bidder wasn’t the best value. Oregon State research confirms LCCA evaluates initial construction costs plus all maintenance costs during service life for true value assessment. A 2025 study by Daoud found asphalt pavement construction demonstrated the lowest user cost due to shorter construction duration. These findings guide informed contractor selection beyond initial bid prices.