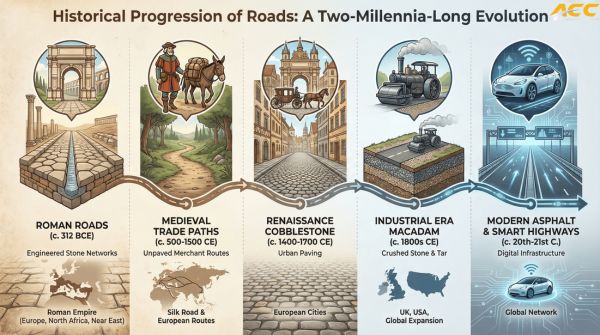

When we consider the infrastructure that connects our modern world, paved roads stand as one of humanity’s most enduring achievements. The history of paved roads is a chronicle of engineering innovation, economic expansion, and societal transformation spanning over two millennia. From ancient stone pathways to modern smart highways, the evolution of road construction reflects our continuous quest to overcome geographical barriers and unite distant communities.

According to historical records, the Roman road system at its peak spanned over 50,000 miles (80,000 km) of hard-surfaced highways, creating an unprecedented network that remained unmatched for centuries. By Emperor Diocletian’s reign, 372 main roads totaling approximately 90,000 km connected the empire’s most distant provinces to Rome itself.

As Professor Erick Guerra from the University of Pennsylvania notes, “Transportation runs on supply and demand. When you increase capacity, you lower the cost of using it, and demand rises to fill the road. Research shows almost a one-to-one relationship between widening highways and increasing traffic—what’s known as the ‘fundamental law of road congestion.'”

Key insights from our comprehensive analysis include: Roman engineers pioneered multi-layered road construction using stone foundations, concrete, and sophisticated drainage systems. Medieval trade routes emerged from Roman remnants, with the Commercial Revolution spurring new road development. The Industrial Revolution introduced macadamization and mechanized construction techniques. Modern materials like asphalt and concrete transformed 20th-century road building. Environmental considerations now drive sustainable construction innovations. Maintenance technologies including self-healing asphalt promise extended road lifespans.

This historical journey reveals how road construction evolved from Roman military highways to medieval trade arteries, then transformed through industrial innovations into today’s complex transportation networks. Each era built upon previous knowledge while addressing new challenges, from accommodating horse-drawn carriages to supporting heavy automobile traffic and preparing for autonomous vehicles.

For immediate application, we recommend considering climate-specific materials when planning road projects and implementing regular maintenance schedules that can extend pavement life by decades rather than years.

As we trace this fascinating evolution from ancient stone paths to modern highways, we’ll discover how each breakthrough in road construction technology addressed the unique challenges of its time while laying the foundation for future innovations.

What Were the Earliest Methods Used to Build Roads?

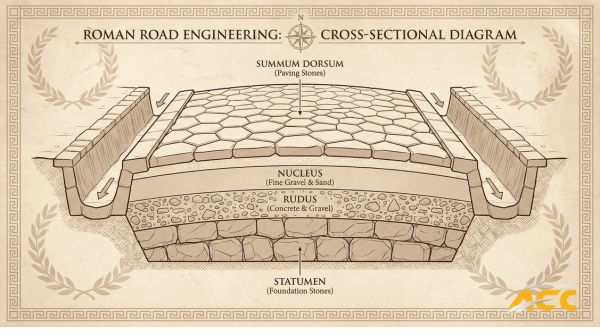

The earliest methods used to build roads involved excavating trenches and layering materials systematically. Roman engineers pioneered these techniques by digging deep foundations and filling them with multiple stone and concrete layers. These ancient construction methods established principles that influenced road building for centuries.

How Did Ancient Civilizations Construct Their Roads?

Ancient civilizations constructed their roads through systematic excavation and layered construction techniques. Roman engineers excavated deep trenches and filled them with stone foundation (statumen), followed by concrete and gravel (rudus), then added the paving surface. The Roman road system spanned over 50,000 miles of hard-surfaced highways at its peak.

By Emperor Diocletian’s reign, 372 main roads totaling approximately 90,000 km connected distant provinces to Rome. Roman roads featured remarkable straightness, solid foundations, and sophisticated drainage systems. Engineers adapted techniques to local conditions while maintaining consistent construction principles across diverse terrains from Northern Africa to Britain.

What Materials Did Early Road Builders Rely On?

Early road builders relied on volcanic ash, lime, and layered stone systems. Romans used concrete incorporating pozzolana (volcanic ash) and lime as a key innovation for longevity. Construction involved multi-layered systems with stone foundation, concrete and gravel middle layer, and paving surface on top.

Materials varied based on local availability while maintaining fundamental construction principles. The Via Egnatia used cobbles, gravel, and mortar with pavement thickness varying from 25 cm on stable ground to over 150 cm in soft areas. Angular crushed stones became crucial in later periods for creating stable, interlocking road surfaces.

What Made Roman Roads So Influential in Paving History?

Roman roads were influential in paving history because of their cambered surfaces and precise engineering standards. Roman roads featured cambered (convex) surfaces ensuring excellent drainage and stability. The Via Egnatia maintained gradients typically of 1-2% but could reach 16-18% in mountainous regions with a maximum 20%.

Road widths ranged from 4-8 meters, expanding to 20 meters in urban centers. Cross-sections had 5-10% grade for rapid drainage, flanked by large rock blocks to prevent lateral spreading. Engineering principles developed by Romans continued influencing road construction for centuries and laid groundwork for modern techniques that companies like Asphalt Coatings Company still apply today.

How Did Road Paving Techniques Evolve During the Middle Ages and Renaissance?

Road paving techniques during the Middle Ages and Renaissance transformed through commercial necessity and urban growth. The Commercial Revolution from the 10th to 14th century drove significant increases in long-distance trade, spurring widespread road development across Europe. Medieval roads initially formed from remnants of Roman routes that had fallen into disrepair after the empire’s decline. These evolving transportation networks would reshape European commerce and society.

What Innovations Emerged in Medieval and Early Modern Road Building?

Medieval and early modern road building innovations emerged primarily from commercial pressures rather than technological breakthroughs. A 10th-century study on European trade routes reveals that new business techniques like partnerships and financial systems developed alongside expanding road networks. Medieval engineers adapted surviving Roman foundations where possible, adding local materials such as timber planking in marshy areas and crushed limestone in quarry regions.

Market integration accelerated as roads improved. According to a 15th-century financial analysis, long-distance convergence in interest rates emerged across European cities, indicating enhanced connectivity. Bridge construction advanced significantly, with stone arch bridges replacing wooden structures at major river crossings. Engineers developed corbelled arch techniques that distributed weight more effectively than Roman designs.

The guild system standardized road maintenance practices across regions. Town charters mandated citizen participation in road repairs, creating Europe’s first systematic maintenance programs. These medieval innovations established foundations for Renaissance improvements.

How Did Trade and Commerce Influence the Need for Better Roads?

The need for better roads intensified as two primary trade networks emerged: the Mediterranean system dominated by Venice and Genoa, and the Northern European network centered around the Baltic and North Seas. Between 1379 and 1384, Genoa’s seaborne trade measured five to six times greater than Lübeck’s, demonstrating the Mediterranean trade’s massive scale and its demand for supporting road infrastructure.

Trade growth continued despite the Black Death’s economic impact in the mid-14th century. A 14th-century economic study on post-plague recovery found that England and Baltic regions maintained expanding commerce through improved overland routes. Medieval trade routes connected wool producers in England with textile manufacturers in Flanders, spice importers in Venice with markets in Germany, and grain suppliers in Eastern Europe with urban centers westward.

Commercial pressure drove technical improvements. Merchants funded toll roads with paved surfaces along heavily trafficked routes. Banking houses established relay stations requiring standardized road widths for wagon passage. These commercial demands accelerated the transition from dirt tracks to engineered roadways throughout Renaissance Europe.

What Role Did Cobblestone and Other Surfaces Play in Urban Roadways?

Cobblestone surfaces revolutionized urban roadways during the medieval and Renaissance periods. Cities began installing cobblestone pavements in market squares and main thoroughfares starting in the 12th century. These durable surfaces consisted of rounded river stones or quarried granite blocks set in sand or mortar beds.

Urban paving materials varied by regional availability:

| City | Year | Source | Paving Material |

| Paris | 1292 | Municipal records | Limestone blocks |

| Venice | 1340 | Construction logs | Istrian stone slabs |

| London | 1358 | City ordinance | Gravel over chalk base |

| Prague | 1400 | Guild records | Granite cobblestones |

Cobblestone installation required skilled craftsmen who shaped stones for tight interlocking patterns. Cities established paving guilds that regulated construction standards and maintenance schedules. Drainage channels ran alongside cobblestone streets, preventing water damage that plagued unpaved roads.

The Renaissance brought refined paving techniques including cambered surfaces for water runoff and standardized stone sizes for smoother riding surfaces. These urban improvements demonstrated how medieval and Renaissance road builders adapted ancient principles to contemporary needs, setting precedents for modern street construction.

When Did Asphalt and Concrete Become Popular Materials for Paved Roads?

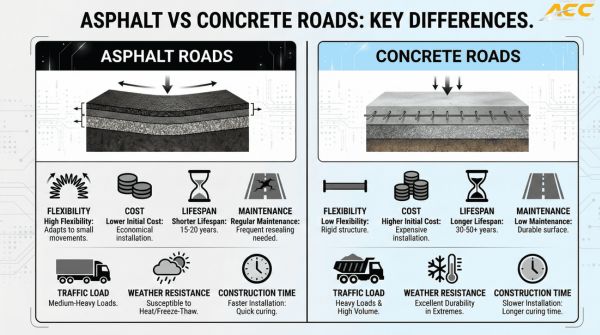

Asphalt and concrete became popular materials for paved roads during the late 19th and early 20th centuries as automobile traffic increased. Hot mix asphalt emerged as the dominant pavement type through heating bitumen with aggregates, while concrete provided a rigid alternative for heavy-traffic areas.

How Was Asphalt First Developed and Used for Roads?

Asphalt was first developed for roads through the introduction of tar as a binding agent for crushed stone, creating “tarmac”—a portmanteau of tar and macadam. Hot mix asphalt (HMA) became the most widely used pavement type by heating bitumen and aggregates before mixing. Modern asphalt pavements consist of 93-97% aggregates such as crushed stone, gravel, and sand combined with 3-7% petroleum-based bitumen binder.

The tarmac development reduced dust and created smoother riding surfaces, laying groundwork for 20th century asphalt roads. Modern asphalt pavements last up to 25 years with proper installation and maintenance.

When Did Concrete Begin Replacing Other Road Materials?

Concrete began replacing other road materials in the early 20th century when engineers sought more durable solutions for increasing traffic loads. Concrete pavements combine cement, water, and aggregates with the water-to-cement ratio being critical for strength. These rigid pavements require stable subgrade conditions, unlike flexible asphalt surfaces.

Concrete roads exceed 40 years lifespan with minimal maintenance despite higher initial construction costs compared to asphalt. The material resists wear from heavy traffic and extreme weather conditions better than asphalt alternatives.

What Are the Key Differences Between Asphalt and Concrete Roads?

The key differences between asphalt and concrete roads are flexibility, cost, and lifespan. Asphalt pavements are flexible surfaces that conform to subgrade variations, while concrete pavements form rigid slabs requiring stable foundations. Initial construction costs favor asphalt with lower upfront investment, whereas concrete demands higher initial expenditure.

Maintenance requirements differ significantly between materials. Asphalt requires more frequent maintenance but offers easier repair options than concrete. Durability spans vary considerably: asphalt lasts up to 25 years with regular maintenance, while concrete exceeds 40 years with minimal upkeep. These material differences shaped how modern road networks developed to meet varying traffic and environmental demands.

What Technological Advancements Transformed Road Construction in the 19th and 20th Centuries?

The technological advancements that transformed road construction in the 19th and 20th centuries include mechanization, new materials, and engineering innovations. Steam-powered machinery replaced manual labor. Engineers developed scientific approaches to road building. The automobile revolution drove rapid evolution in paving techniques and standards.

How Did Steam Power and Machinery Change Road Building?

Steam power and machinery changed road building by enabling faster construction and improved compaction methods. John Loudon McAdam (1756-1836) developed macadamisation using compacted crushed stone, creating strong water-resistant surfaces. McAdam’s process used angular crushed stones that locked together forming dense, stable layers.

Thomas Telford (1757-1834) constructed over 1,000 miles of new roads in Scotland using hand-placed foundation stones. Telford’s method cost more but created exceptionally durable roads capable of withstanding heavy traffic. The 20th century brought steam rollers and mechanized spreaders. These machines enabled construction of vast highway networks at unprecedented speeds.

What Impact Did Automobiles Have on Paving Techniques?

Automobiles impacted paving techniques by demanding smoother, more durable road surfaces. The shift from horse-friendly surfaces to motorized vehicle pavements required new materials and construction methods. Roads needed to handle increasing traffic volume and weight.

Highway expansion became the conventional approach to managing congestion. Research shows a one-to-one relationship between road widening and increased traffic. Modern autonomous vehicles require smart roads with embedded sensors and communication systems. These technological demands continue driving innovation in paving materials and techniques.

How Did Road Standards and Regulations Develop Over Time?

Road standards and regulations developed through gradual establishment of engineering specifications and safety requirements. Early standards focused on width, gradient, and drainage. The 20th century brought comprehensive design manuals and construction codes.

Government agencies established material testing protocols and quality control measures. Standards evolved to address vehicle speeds, weights, and traffic volumes. International cooperation led to harmonized specifications for cross-border highways. Modern regulations incorporate environmental protection, accessibility requirements, and lifecycle cost analysis into road construction planning.

How Do Environmental and Social Factors Influence the Development of Paved Roads?

Environmental and social factors influence the development of paved roads through greenhouse gas emissions, urbanization patterns, and sustainability challenges. Road pavements produced approximately 24% of total greenhouse gas emissions over the last century, fundamentally shaping modern construction approaches. These factors drive innovations in materials, design standards, and construction methods across diverse climates and communities.

What Environmental Considerations Affect Paving Projects?

Environmental considerations affect paving projects through emissions, water management, and climate adaptation requirements. Road pavements produced approximately 24% of total greenhouse gas emissions over the last century according to industry analysis. Canadian asphalt binders have carbon footprints ranging from 826 to 1,098 kgCO2eq/t, potentially higher with fugitive emissions.

A 2021 MIT study on carbon-neutral pavements suggests net-zero roads possible by 2050 with 38% reduction in concrete’s embodied impact and 14% for asphalt. Permeable pavements allow rainwater infiltration, reducing stormwater runoff and improving water quality in urban watersheds. Climate change forces engineers to design roads with elevated roadbeds for flood protection and heat-resistant materials for extreme temperatures.

Modern paving projects must balance environmental impacts with durability needs, requiring innovative materials and construction techniques that minimize ecological footprints while maintaining structural integrity.

How Have Paved Roads Impacted Urbanization and Society?

Paved roads have impacted urbanization and society by serving as arteries of empires, facilitating trade, communication, and the spread of ideas throughout history. Roman roads proved instrumental in conquest, administration, and diffusion of Christianity across Europe. Medieval roads enabled the Commercial Revolution and rise of major trade centers such as Venice, Genoa, and Lübeck.

Modern highway construction faces criticism for environmental damage, increased car dependency, and higher traffic fatalities. Roads shape settlement patterns, determining where communities develop and how populations interact. Infrastructure networks influence economic opportunities, access to services, and social mobility across regions.

The relationship between roads and society remains complex, with benefits of connectivity balanced against environmental and social costs that continue shaping policy debates worldwide.

What Are the Modern Challenges in Sustainable Road Construction?

The modern challenges in sustainable road construction are energy-intensive production processes, regional climate adaptations, and extreme weather resilience. Production of both asphalt and concrete generates significant greenhouse gas emissions during manufacturing and transportation. Desert regions require sand stabilization using geocells and soil stabilizers to prevent shifting and erosion.

| Region Type | Environmental Challenge | Construction Requirement / Method |

| Permafrost regions | Frozen ground instability | Insulation and elevated roadbeds |

| Tropical regions | Heavy rainfall | Robust drainage systems |

| Coastal areas | Rising sea levels | Flood-adaptive design (inferred) |

| Desert zones | Shifting sands, erosion | Geocells and soil stabilizers |

Rising sea levels and extreme weather events require climate-resilient road designs incorporating advanced materials and adaptive engineering. Engineers must balance durability, cost, and environmental impact while meeting increasing traffic demands and stricter emissions regulations across diverse geographical conditions.

How Is the Maintenance and Longevity of Paved Roads Ensured?

The maintenance and longevity of paved roads is ensured through regular preventive maintenance, strategic resurfacing programs, and innovative technologies that extend pavement life. Modern road maintenance combines traditional repair techniques with advanced materials like self-healing asphalt and smart monitoring systems. These approaches help road surfaces withstand traffic loads, weather extremes, and aging while minimizing lifecycle costs.

What Are the Most Common Maintenance Techniques for Paved Surfaces?

The most common maintenance techniques for paved surfaces include crack sealing, pothole patching, seal coating, and drainage system repairs. Self-healing asphalt represents a breakthrough technology that automatically repairs cracks and potholes, potentially doubling road lifespan from 25 to 50 years. Asphalt pavements require maintenance every 3-5 years, while concrete roads need major repairs only every 10-15 years.

Proper drainage systems prevent water infiltration that causes base erosion and pavement failure. There are four essential drainage maintenance practices:

- Regular cleaning of catch basins and storm drains

- Repairing damaged edge drains and subsurface pipes

- Maintaining proper road crown for surface water runoff

- Installing French drains in areas with high groundwater

Recycled materials now comprise up to 30% of maintenance materials in many jurisdictions. Reclaimed asphalt pavement (RAP) and recycled concrete aggregate reduce costs while maintaining performance standards. These sustainable practices lower environmental impact while preserving road quality through routine maintenance cycles.

How Does Asphalt Resurfacing Help Extend Road Life?

Asphalt resurfacing extends road life by adding a new wear layer that restores surface smoothness, improves drainage, and seals underlying pavement from moisture infiltration. The resurfacing process involves milling the deteriorated top layer and applying 1.5-2 inches of fresh hot mix asphalt. This technique can add 8-15 years to pavement life at one-third the cost of full reconstruction.

Resurfacing timing is critical for maximizing benefits. Roads should be resurfaced when surface distress appears but before structural damage occurs. Key indicators include extensive cracking patterns, rutting exceeding 0.5 inches, and raveling that exposes aggregate.

Modern resurfacing incorporates polymer-modified asphalts that resist rutting and thermal cracking. Warm-mix asphalt technologies reduce production temperatures by 30-40°F, cutting emissions while maintaining durability. These advances make resurfacing an increasingly effective strategy for preserving road infrastructure investments.

What Innovations Improve the Durability of Modern Roads?

Innovations that improve the durability of modern roads include self-healing materials, geocell reinforcement systems, and smart monitoring technologies. Self-healing asphalt contains capsules of rejuvenating agents that activate when cracks form, automatically sealing damage before water penetration occurs. These materials can repair cracks up to 6mm wide without human intervention.

Climate-appropriate material selection enhances durability in challenging environments. There are three critical adaptations for extreme conditions:

- Desert regions: geocells filled with local sand create load-bearing surfaces resistant to wind erosion

- Cold climates: lime-activated slag mixed with crushed sand prevents frost heaving

- Tropical areas: polymer-modified binders resist softening at temperatures exceeding 140°F

Smart road technologies integrate sensors that monitor pavement condition, traffic loads, and environmental factors in real-time. These systems detect subsurface deterioration before visible damage appears, enabling predictive maintenance that extends service life by 20-30%. The combination of advanced materials and intelligent monitoring creates road infrastructure capable of lasting decades with minimal intervention.

How Can Businesses Like Asphalt Coatings Support Quality Road Paving?

Businesses like Asphalt Coatings Company support quality road paving through specialized materials, professional application techniques, and maintenance services that extend pavement life. Modern paving contractors combine centuries of engineering knowledge with advanced technology to deliver durable surfaces. The following services and historical insights demonstrate how professional paving companies continue the evolution of road construction methods developed over millennia.

What Services Does Asphalt Coatings Company Offer for Road Paving and Repair?

Asphalt Coatings Company offers comprehensive paving services including hot mix asphalt installation, sealcoating, crack filling, and complete resurfacing projects. Professional contractors apply hot mix asphalt containing 93-97% aggregates and 3-7% bitumen binder at precise temperatures to ensure proper bonding. Sealcoating services protect asphalt surfaces from water penetration, UV damage, and chemical spills by applying protective polymer-modified coatings every 2-3 years.

Repair services address common pavement failures such as cracking, potholes, and surface deterioration through targeted interventions. Crack filling prevents water infiltration using rubberized asphalt compounds that flex with temperature changes. Full-depth patching removes damaged sections down to the base layer before installing new asphalt. Overlay applications add fresh asphalt layers over existing surfaces after proper preparation.

| Service Type | Component / Process | Key Attributes | Frequency / Lifespan | Benefits |

| Hot Mix Asphalt | Aggregates & Bitumen | 93–97% aggregates, 3–7% bitumen | Applied as needed | Strong bonding, flexible under temperature changes |

| Sealcoating | Protective Coating | Polymer-modified sealant | Every 2–3 years | UV, water & chemical resistance |

| Crack Filling | Rubberized Asphalt Compound | Flexible with thermal shifts | As needed (preventive) | Prevents water infiltration, extends pavement life |

| Full-Depth Patching | Structural Repair | Removal to base layer, new asphalt installed | As needed (repair) | Corrects major damage like potholes |

| Asphalt Overlay | Surface Resurfacing | New asphalt layer over prepped surface | Periodic resurfacing | Restores surface, delays full replacement |

Professional paving companies ensure quality through proper base preparation, correct material selection, and precise application temperatures. These services directly connect to historical road-building principles while incorporating modern materials and equipment for superior results.

What Are the Key Takeaways About the History of Paved Roads?

The key takeaways about the history of paved roads are the continuous evolution of materials, techniques, and engineering principles that created today’s modern infrastructure. Roman engineers established fundamental concepts including multi-layered construction, proper drainage, and locally adapted materials that remain central to modern paving. Their 50,000-mile network demonstrated how quality roads enable commerce, communication, and cultural exchange across vast territories.

Medieval and Renaissance periods saw road development driven by commercial needs, with trade networks spanning from the Mediterranean to the Baltic requiring reliable transportation routes. The 19th century brought revolutionary changes through McAdam’s macadamization process using angular crushed stones and mechanized construction equipment. According to historical records, Thomas Telford constructed over 1,000 miles of roads in Scotland using hand-placed foundation stones, creating exceptionally durable surfaces.

Modern paving faces environmental challenges with road pavements producing approximately 24% of total greenhouse gas emissions over the last century. A 2021 MIT study suggests carbon-neutral pavements are possible by 2050 with 38% reduction in concrete’s embodied impact and 14% for asphalt. Today’s paving companies like Asphalt Coatings Company apply these historical lessons while addressing sustainability through recycled materials, permeable surfaces, and self-healing technologies that could double road lifespans.